Page 34 - Construction Waterproofing Handbook

P. 34

1.16 CHAPTER ONE

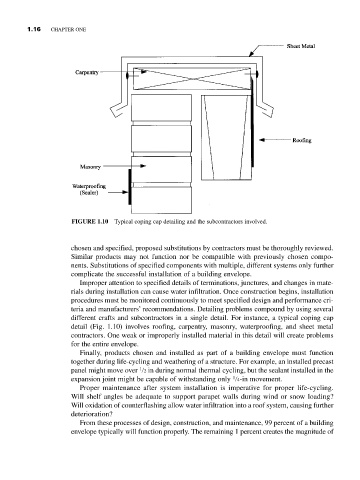

FIGURE 1.10 Typical coping cap detailing and the subcontractors involved.

chosen and specified, proposed substitutions by contractors must be thoroughly reviewed.

Similar products may not function nor be compatible with previously chosen compo-

nents. Substitutions of specified components with multiple, different systems only further

complicate the successful installation of a building envelope.

Improper attention to specified details of terminations, junctures, and changes in mate-

rials during installation can cause water infiltration. Once construction begins, installation

procedures must be monitored continuously to meet specified design and performance cri-

teria and manufacturers’ recommendations. Detailing problems compound by using several

different crafts and subcontractors in a single detail. For instance, a typical coping cap

detail (Fig. 1.10) involves roofing, carpentry, masonry, waterproofing, and sheet metal

contractors. One weak or improperly installed material in this detail will create problems

for the entire envelope.

Finally, products chosen and installed as part of a building envelope must function

together during life-cycling and weathering of a structure. For example, an installed precast

1

panel might move over 2 in during normal thermal cycling, but the sealant installed in the

1

expansion joint might be capable of withstanding only 4-in movement.

Proper maintenance after system installation is imperative for proper life-cycling.

Will shelf angles be adequate to support parapet walls during wind or snow loading?

Will oxidation of counterflashing allow water infiltration into a roof system, causing further

deterioration?

From these processes of design, construction, and maintenance, 99 percent of a building

envelope typically will function properly. The remaining 1 percent creates the magnitude of