Page 71 - Construction Waterproofing Handbook

P. 71

BELOW-GRADE WATERPROOFING 2.35

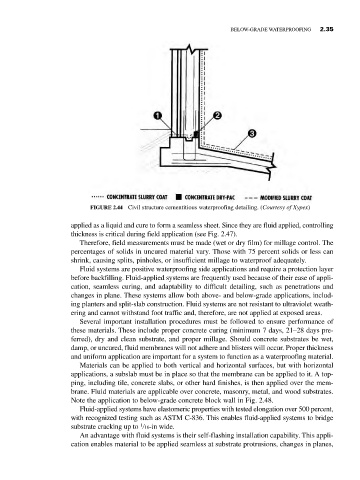

FIGURE 2.44 Civil structure cementitious waterproofing detailing. (Courtesy of Xypex)

applied as a liquid and cure to form a seamless sheet. Since they are fluid applied, controlling

thickness is critical during field application (see Fig. 2.47).

Therefore, field measurements must be made (wet or dry film) for millage control. The

percentages of solids in uncured material vary. Those with 75 percent solids or less can

shrink, causing splits, pinholes, or insufficient millage to waterproof adequately.

Fluid systems are positive waterproofing side applications and require a protection layer

before backfilling. Fluid-applied systems are frequently used because of their ease of appli-

cation, seamless curing, and adaptability to difficult detailing, such as penetrations and

changes in plane. These systems allow both above- and below-grade applications, includ-

ing planters and split-slab construction. Fluid systems are not resistant to ultraviolet weath-

ering and cannot withstand foot traffic and, therefore, are not applied at exposed areas.

Several important installation procedures must be followed to ensure performance of

these materials. These include proper concrete curing (minimum 7 days, 21–28 days pre-

ferred), dry and clean substrate, and proper millage. Should concrete substrates be wet,

damp, or uncured, fluid membranes will not adhere and blisters will occur. Proper thickness

and uniform application are important for a system to function as a waterproofing material.

Materials can be applied to both vertical and horizontal surfaces, but with horizontal

applications, a subslab must be in place so that the membrane can be applied to it. A top-

ping, including tile, concrete slabs, or other hard finishes, is then applied over the mem-

brane. Fluid materials are applicable over concrete, masonry, metal, and wood substrates.

Note the application to below-grade concrete block wall in Fig. 2.48.

Fluid-applied systems have elastomeric properties with tested elongation over 500 percent,

with recognized testing such as ASTM C-836. This enables fluid-applied systems to bridge

1

substrate cracking up to 16-in wide.

An advantage with fluid systems is their self-flashing installation capability. This appli-

cation enables material to be applied seamless at substrate protrusions, changes in planes,