Page 402 - Corrosion Engineering Principles and Practice

P. 402

370 C h a p t e r 9 A t m o s p h e r i c C o r r o s i o n 371

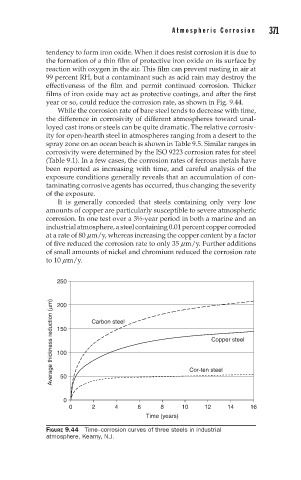

tendency to form iron oxide. When it does resist corrosion it is due to

the formation of a thin film of protective iron oxide on its surface by

reaction with oxygen in the air. This film can prevent rusting in air at

99 percent RH, but a contaminant such as acid rain may destroy the

effectiveness of the film and permit continued corrosion. Thicker

films of iron oxide may act as protective coatings, and after the first

year or so, could reduce the corrosion rate, as shown in Fig. 9.44.

While the corrosion rate of bare steel tends to decrease with time,

the difference in corrosivity of different atmospheres toward unal-

loyed cast irons or steels can be quite dramatic. The relative corrosiv-

ity for open-hearth steel in atmospheres ranging from a desert to the

spray zone on an ocean beach is shown in Table 9.5. Similar ranges in

corrosivity were determined by the ISO 9223 corrosion rates for steel

(Table 9.1). In a few cases, the corrosion rates of ferrous metals have

been reported as increasing with time, and careful analysis of the

exposure conditions generally reveals that an accumulation of con-

taminating corrosive agents has occurred, thus changing the severity

of the exposure.

It is generally conceded that steels containing only very low

amounts of copper are particularly susceptible to severe atmospheric

corrosion. In one test over a 3½-year period in both a marine and an

industrial atmosphere, a steel containing 0.01 percent copper corroded

at a rate of 80 mm/y, whereas increasing the copper content by a factor

of five reduced the corrosion rate to only 35 mm/y. Further additions

of small amounts of nickel and chromium reduced the corrosion rate

to 10 mm/y.

250

Average thickness reduction (mm) 150 Carbon steel Cor-ten steel

200

Copper steel

100

50

0

0 2 4 6 8 10 12 14 16

Time (years)

FIGURE 9.44 Time–corrosion curves of three steels in industrial

atmosphere, Kearny, N.J.