Page 417 - Corrosion Engineering Principles and Practice

P. 417

386 C h a p t e r 1 0 C o r r o s i o n i n S o i l s a n d M i c r o b i o l o g i c a l l y I n f l u e n c e d C o r r o s i o n 387

Air

5

7, 8 Aluminum and 11

5

5

2 4, 5, 8 Polymers alloys

6

alloys Oil

Ferrous 2 1 Emulsions

2 Water 10 5 2, 5

6

5

Plastics

Soil 2 7, 8, 9

2 2 2, 5

Atomic H Hessian

Various metals

2, 3 5

2

Concrete Asphalt bitume

3

4

Protective coatings

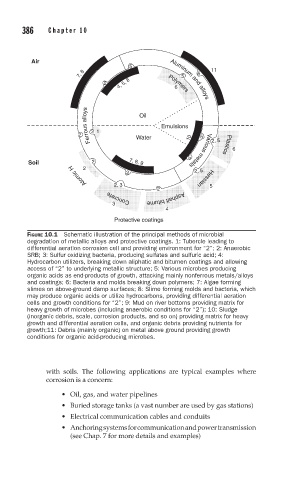

FIGURE 10.1 Schematic illustration of the principal methods of microbial

degradation of metallic alloys and protective coatings. 1: Tubercle leading to

differential aeration corrosion cell and providing environment for “2”; 2: Anaerobic

SRB; 3: Sulfur oxidizing bacteria, producing sulfates and sulfuric acid; 4:

Hydrocarbon utilizers, breaking down aliphatic and bitumen coatings and allowing

access of “2” to underlying metallic structure; 5: Various microbes producing

organic acids as end-products of growth, attacking mainly nonferrous metals/alloys

and coatings; 6: Bacteria and molds breaking down polymers; 7: Algae forming

slimes on above-ground damp surfaces; 8: Slime forming molds and bacteria, which

may produce organic acids or utilize hydrocarbons, providing differential aeration

cells and growth conditions for “2”; 9: Mud on river bottoms providing matrix for

heavy growth of microbes (including anaerobic conditions for “2”); 10: Sludge

(inorganic debris, scale, corrosion products, and so on) providing matrix for heavy

growth and differential aeration cells, and organic debris providing nutrients for

growth;11: Debris (mainly organic) on metal above ground providing growth

conditions for organic acid-producing microbes.

with soils. The following applications are typical examples where

corrosion is a concern:

• Oil, gas, and water pipelines

• Buried storage tanks (a vast number are used by gas stations)

• Electrical communication cables and conduits

• Anchoring systems for communication and power transmission

(see Chap. 7 for more details and examples)