Page 479 - Corrosion Engineering Principles and Practice

P. 479

446 C h a p t e r 1 1 M a t e r i a l s S e l e c t i o n , Te s t i n g , a n d D e s i g n C o n s i d e r a t i o n s 447

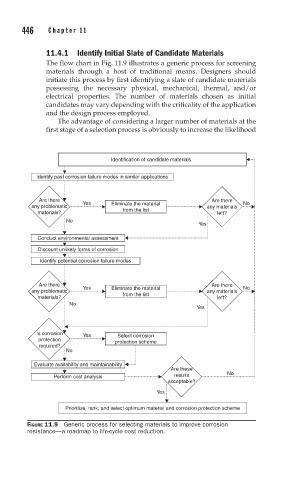

11.4.1 Identify Initial Slate of Candidate Materials

The flow chart in Fig. 11.9 illustrates a generic process for screening

materials through a host of traditional means. Designers should

initiate this process by first identifying a slate of candidate materials

possessing the necessary physical, mechanical, thermal, and/or

electrical properties. The number of materials chosen as initial

candidates may vary depending with the criticality of the application

and the design process employed.

The advantage of considering a larger number of materials at the

first stage of a selection process is obviously to increase the likelihood

Identification of candidate materials

Identify past corrosion failure modes in similar applications

Are there Are there

any problematic Yes Eliminate the material any materials No

materials? from the list left?

No

Yes

Conduct environmental assessment

Discount unlikely forms of corrosion

Identify potential corrosion failure modes

Are there Are there

any problematic Yes Eliminate the material any materials No

materials? from the list left?

No

Yes

Is corrosion Yes Select corrosion

protection protection scheme

required?

No

Evaluate availability and maintainability

Are these

Perform cost analysis results No

acceptable?

Yes

Prioritize, rank, and select optimum material and corrosion protection scheme

FIGURE 11.9 Generic process for selecting materials to improve corrosion

resistance—a roadmap to life-cycle cost reduction.