Page 499 - Corrosion Engineering Principles and Practice

P. 499

466 C h a p t e r 1 1 M a t e r i a l s S e l e c t i o n , Te s t i n g , a n d D e s i g n C o n s i d e r a t i o n s 467

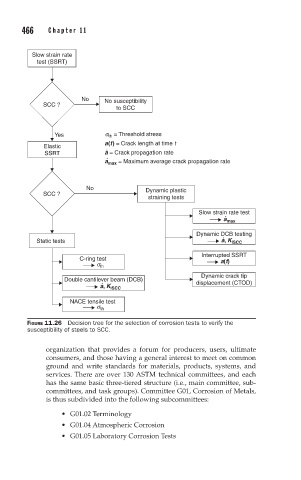

Slow strain rate

test (SSRT)

No No susceptibility

SCC ?

to SCC

Yes s = Threshold stress

th

Elastic a(t) = Crack length at time t

SSRT a = Crack propagation rate

a max = Maximum average crack propagation rate

No Dynamic plastic

SCC ?

straining tests

Slow strain rate test

a max

Dynamic DCB testing

Static tests a, K ISCC

Interrupted SSRT

C-ring test a(t)

s th

Dynamic crack tip

Double cantilever beam (DCB) displacement (CTOD)

a, K ISCC

NACE tensile test

s th

FIGURE 11.26 Decision tree for the selection of corrosion tests to verify the

susceptibility of steels to SCC.

organization that provides a forum for producers, users, ultimate

consumers, and those having a general interest to meet on common

ground and write standards for materials, products, systems, and

services. There are over 130 ASTM technical committees, and each

has the same basic three-tiered structure (i.e., main committee, sub-

committees, and task groups). Committee G01, Corrosion of Metals,

is thus subdivided into the following subcommittees:

• G01.02 Terminology

• G01.04 Atmospheric Corrosion

• G01.05 Laboratory Corrosion Tests