Page 335 - Design for Environment A Guide to Sustainable Product Development

P. 335

310 Cha pte r Se v e ntee n

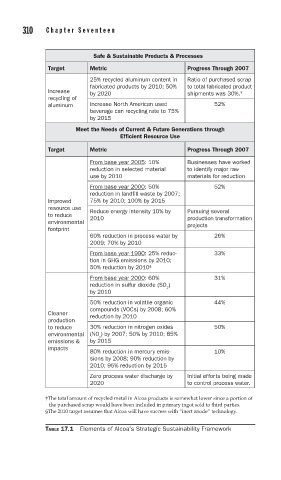

Safe & Sustainable Products & Processes

Target Metric Progress Through 2007

25% recycled aluminum content in Ratio of purchased scrap

fabricated products by 2010; 50% to total fabricated product

Increase

by 2020 shipments was 30%. ‡

recycling of

aluminum Increase North American used 52%

beverage can recycling rate to 75%

by 2015

Meet the Needs of Current & Future Generations through

Efficient Resource Use

Target Metric Progress Through 2007

From base year 2005: 10% Businesses have worked

reduction in selected material to identify major raw

use by 2010 materials for reduction

From base year 2000: 50% 52%

reduction in landfill waste by 2007;

Improved 75% by 2010; 100% by 2015

resource use Reduce energy intensity 10% by Pursuing several

to reduce 2010 production transformation

environmental

projects

footprint

60% reduction in process water by 26%

2009; 70% by 2010

From base year 1990: 25% reduc- 33%

tion in GHG emissions by 2010;

50% reduction by 2010 §

From base year 2000: 60% 31%

reduction in sulfur dioxide (SO )

2

by 2010

50% reduction in volatile organic 44%

compounds (VOCs) by 2008; 60%

Cleaner

reduction by 2010

production

to reduce 30% reduction in nitrogen oxides 50%

environmental (NO ) by 2007; 50% by 2010; 85%

x

emissions & by 2015

impacts

80% reduction in mercury emis- 10%

sions by 2008; 90% reduction by

2010; 95% reduction by 2015

Zero process water discharge by Initial efforts being made

2020 to control process water.

‡The total amount of recycled metal in Alcoa products is somewhat lower since a portion of

the purchased scrap would have been included in primary ingot sold to third parties.

§The 2010 target assumes that Alcoa will have success with “inert anode” technology.

TABLE 17.1 Elements of Alcoa's Strategic Sustainability Framework