Page 57 - Design of Reinforced Masonry Structures

P. 57

2.10 CHAPTER TWO

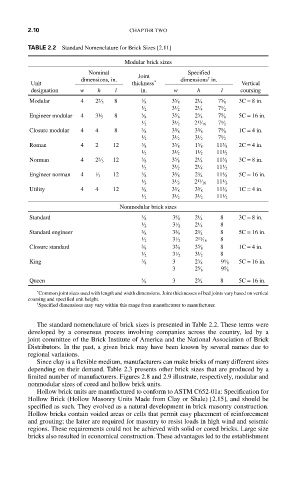

TABLE 2.2 Standard Nomenclature for Brick Sizes [2.11]

Modular brick sizes

Nominal Specified

†

dimensions, in. Joint dimensions in.

Unit thickness * Vertical

designation w h l in. w h l coursing

Modular 4 2 2 ⁄ 3 8 3 ⁄ 8 3 5 ⁄ 8 2 1 ⁄ 4 7 5 ⁄ 8 3C = 8 in.

3 1 ⁄ 2 2 1 ⁄ 4 7 1 ⁄ 2

1 ⁄ 2

Engineer modular 4 3 1 ⁄ 5 8 3 ⁄ 8 3 5 ⁄ 8 2 3 ⁄ 4 7 5 ⁄ 8 5C = 16 in.

1 ⁄ 2 3 1 ⁄ 2 2 13 ⁄ 16 7 1 ⁄ 2

Closure modular 4 4 8 3 ⁄ 8 3 5 ⁄ 8 3 5 ⁄ 8 7 5 ⁄ 8 1C = 4 in.

1 ⁄ 2

3 1 ⁄ 2 3 1 ⁄ 2 7 1 ⁄ 2

Roman 4 2 12 3 ⁄ 8 3 5 ⁄ 8 1 5 ⁄ 8 11 5 ⁄ 8 2C = 4 in.

1 ⁄ 2

3 1 ⁄ 2 1 1 ⁄ 2 11 1 ⁄ 2

Norman 4 2 2 ⁄ 3 12 3 ⁄ 8 3 5 ⁄ 8 2 1 ⁄ 4 11 5 ⁄ 8 3C = 8 in.

1 ⁄ 2

3 1 ⁄ 2 2 1 ⁄ 4 11 1 ⁄ 2

Engineer norman 4 1 ⁄ 3 12 3 ⁄ 8 3 5 ⁄ 8 2 3 ⁄ 4 11 5 ⁄ 8 5C = 16 in.

1 ⁄ 2 3 1 ⁄ 2 2 13 ⁄ 16 11 1 ⁄ 2

Utility 4 4 12 3 ⁄ 8 3 5 ⁄ 8 3 5 ⁄ 8 11 5 ⁄ 8 1C = 4 in.

1 ⁄ 2

3 1 ⁄ 2 3 1 ⁄ 2 11 1 ⁄ 2

Nonmodular brick sizes

Standard 3 ⁄ 8 3 5 ⁄ 8 2 1 ⁄ 4 8 3C = 8 in.

3 1 ⁄ 2 2 1 ⁄ 4

1 ⁄ 2 8

Standard engineer 3 ⁄ 8 3 5 ⁄ 8 2 3 ⁄ 4 8 5C = 16 in.

3 1 ⁄ 2 2 13 ⁄ 16

1 ⁄ 2 8

Closure standard 3 ⁄ 8 3 5 ⁄ 8 3 5 ⁄ 8 8 1C = 4 in.

8

1 ⁄ 2 3 1 ⁄ 2 3 1 ⁄ 2

King 3 ⁄ 8 3 2 3 ⁄ 4 9 5 ⁄ 8 5C = 16 in.

3 2 5 ⁄ 8 9 5 ⁄ 8

Queen 3 ⁄ 8 3 2 3 ⁄ 4 8 5C = 16 in.

*

Common joint sizes used with length and width dimensions. Joint thicknesses of bed joints vary based on vertical

coursing and specified unit height.

†

Specified dimensions may vary within this range from manufacturer to manufacturer.

The standard nomenclature of brick sizes is presented in Table 2.2. These terms were

developed by a consensus process involving companies across the country, led by a

joint committee of the Brick Institute of America and the National Association of Brick

Distributors. In the past, a given brick may have been known by several names due to

regional variations.

Since clay is a flexible medium, manufacturers can make bricks of many different sizes

depending on their demand. Table 2.3 presents other brick sizes that are produced by a

limited number of manufacturers. Figures 2.8 and 2.9 illustrate, respectively, modular and

nonmodular sizes of cored and hollow brick units.

Hollow brick units are manufactured to conform to ASTM C652-01a: Specification for

Hollow Brick (Hollow Masonry Units Made from Clay or Shale) [2.15], and should be

specified as such. They evolved as a natural development in brick masonry construction.

Hollow bricks contain voided areas or cells that permit easy placement of reinforcement

and grouting; the latter are required for masonry to resist loads in high wind and seismic

regions. These requirements could not be achieved with solid or cored bricks. Large size

bricks also resulted in economical construction. These advantages led to the establishment