Page 76 - Design of Reinforced Masonry Structures

P. 76

MASONRY UNITS: APPLICATIONS, TYPES, SIZES, AND CLASSIFICATION 2.29

they can be placed conveniently around the reinforcing bars already in place. The major

advantage of this is the elimination of the need to lift the units over the tops of the rein-

forcing bar or to thread the reinforcement through the cores after the wall is constructed

(Fig. 2.21). Bond beam and lintel units are essentially U- or channel-shaped units that

are used to accommodate horizontal reinforcement. Bond beam units are characterized

by depressed webs to accommodate horizontal reinforcing bars. They are produced

either with reduced webs, or with “knock-out” webs which are removed prior to place-

ment in the wall. Lintel units are produced in various depths that may be required to

carry desired lintel loads over the door and window openings. The solid bottoms in

both bond beam and lintel units confine the grout. Pilaster and column units are used

to accommodate wall-column or wall-pilaster interface, and allow space for load-carrying

reinforcement.

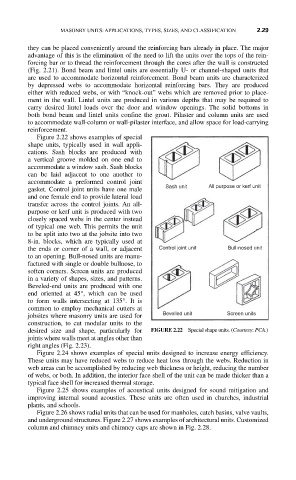

Figure 2.22 shows examples of special

shape units, typically used in wall appli-

cations. Sash blocks are produced with

a vertical groove molded on one end to

accommodate a window sash. Sash blocks

can be laid adjacent to one another to

accommodate a preformed control joint

Sash unit All purpose or kerf unit

gasket. Control joint units have one male

and one female end to provide lateral load

transfer across the control joints. An all-

purpose or kerf unit is produced with two

closely spaced webs in the center instead

of typical one web. This permits the unit

to be split into two at the jobsite into two

8-in. blocks, which are typically used at

the ends or corner of a wall, or adjacent Control joint unit Bull-nosed unit

to an opening. Bull-nosed units are manu-

factured with single or double bullnose, to

soften corners. Screen units are produced

in a variety of shapes, sizes, and patterns.

Beveled-end units are produced with one

end oriented at 45°, which can be used

to form walls intersecting at 135°. It is

common to employ mechanical cutters at

jobsites where masonry units are used for Bevelled unit Screen units

construction, to cut modular units to the

desired size and shape, particularly for FIGURE 2.22 Special shape units. (Courtesy: PCA.)

joints where walls meet at angles other than

right angles (Fig. 2.23).

Figure 2.24 shows examples of special units designed to increase energy efficiency.

These units may have reduced webs to reduce heat loss through the webs. Reduction in

web areas can be accomplished by reducing web thickness or height, reducing the number

of webs, or both. In addition, the interior face shell of the unit can be made thicker than a

typical face shell for increased thermal storage.

Figure 2.25 shows examples of acoustical units designed for sound mitigation and

improving internal sound acoustics. These units are often used in churches, industrial

plants, and schools.

Figure 2.26 shows radial units that can be used for manholes, catch basins, valve vaults,

and underground structures. Figure 2.27 shows examples of architectural units. Customized

column and chimney units and chimney caps are shown in Fig. 2.28.