Page 218 - Design of Simple and Robust Process Plants

P. 218

5.7 Simplification and Ranking per Unit Operation 203

(3)

(1)

F (2)

HEAT HEAT

(4)

(1)

(2)

F (2)

(3)

HEAT

HEAT

(4)

(2) (3)

(1)

F

HEAT

HEAT HEAT

(4)

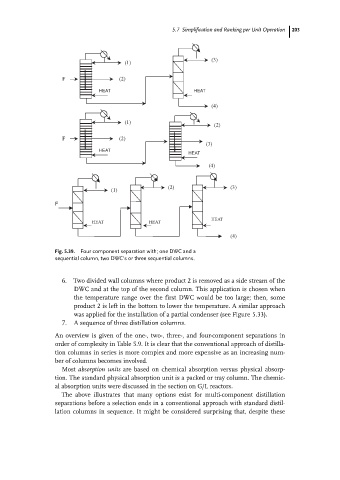

Fig. 5.39. Four component separation with; one DWCand a

sequential column, two DWC's or three sequential columns.

6. Two divided wall columns where product 2 is removed as a side stream of the

DWC and at the top of the second column. This application is chosen when

the temperature range over the first DWC would be too large; then, some

product 2 is left in the bottom to lower the temperature. A similar approach

was applied for the installation of a partial condenser (see Figure 5.33).

7. A sequence of three distillation columns.

An overview is given of the one-, two-, three-, and four-component separations in

order of complexity in Table 5.9. It is clear that the conventional approach of distilla-

tion columns in series is more complex and more expensive as an increasing num-

ber of columns becomes involved.

Most absorption units are based on chemical absorption versus physical absorp-

tion. The standard physical absorption unit is a packed or tray column. The chemic-

al absorption units were discussed in the section on G/L reactors.

The above illustrates that many options exist for multi-component distillation

separations before a selection ends in a conventional approach with standard distil-

lation columns in sequence. It might be considered surprising that, despite these