Page 28 - Design of Simple and Robust Process Plants

P. 28

1.3 Design Philosophies 11

certain percentage of product recycle, which results in a need for more capi-

tal. The concept of ªprevent versus cureº attempts to avoid all these additional

provisions. The solution is consistent operation, which can only be realized

by a certain level of automation and much more attention to feed-forward

control to avoid off-spec situations. Do not build a plant for all types of mis-

haps (excluding safety provisions) ± do it right the first time.

2. Design for first-pass prime. This is a specific case of ªprevent versus cureº. Dur-

ing start-up of a plant, it is often necessary to deal with off-spec situations.

The challenge is how to prevent these and thus avoid all the rework and/or

losses. The answer is to design for first-pass prime, and this often involves

designed start-up procedures. Start a continuous process from the back end,

and put the finishing sections of a plant in hot stand by condition. This

means that the finishing section is at operational and specification condition

(e.g., distillations are at total reflux, compressors run in recycle mode) and

ready to process the feed from the reactor section. In addition, it is necessary

to prepare the reactor for a flying start. This requires a good understanding

of the reactor operation that can be obtained from dynamic simulations, lead-

ing to start-up procedures to achieve first-pass prime. The hardware modifi-

cations to achieve this are limited, and mostly result in minor piping modifi-

cations. A leading article on this subject was produced by Verwijs et al.

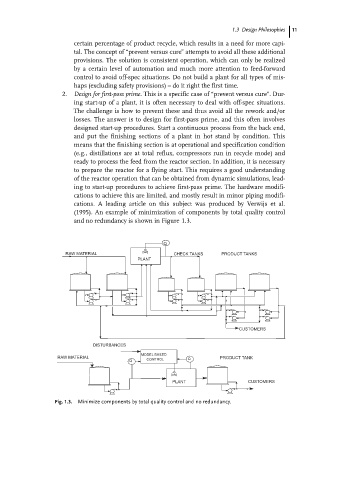

(1995). An example of minimization of components by total quality control

and no redundancy is shown in Figure 1.3.

Q

RAW MATERIAL CHECK TANKS PRODUCT TANKS

PLANT

CUSTOMERS

DISTURBANCES

MODEL BASED

RAW MATERIAL Q PRODUCT TANK

Q CONTROL

PLANT CUSTOMERS

Fig. 1.3. Minimize components by total quality control and no redundancy.