Page 99 - Drilling Technology in Nontechnical Language

P. 99

90 Drilling Technology in Nontechnical Language Second Edition

Hole and Casing Sizes

With a development well, the contingency to run an extra string of

casing if unexpected hole problems are encountered is less important

than on an exploration well. If a well can be drilled one size smaller (for

instance, 20" conductor instead of 30"), generally it will be cheaper to

drill the well by around 15%. There is a strong incentive to avoid building

in unnecessary contingencies against remote possibilities when the cost

penalty is so large.

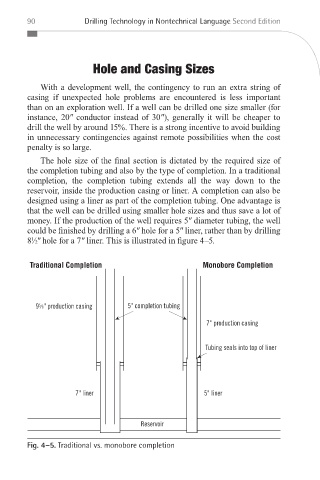

The hole size of the final section is dictated by the required size of

the completion tubing and also by the type of completion. In a traditional

completion, the completion tubing extends all the way down to the

reservoir, inside the production casing or liner. A completion can also be

designed using a liner as part of the completion tubing. One advantage is

that the well can be drilled using smaller hole sizes and thus save a lot of

money. If the production of the well requires 5" diameter tubing, the well

could be finished by drilling a 6" hole for a 5" liner, rather than by drilling

8½" hole for a 7" liner. This is illustrated in figure 4–5.

Fig. 4–5. Traditional vs. monobore completion

_Devereux_Book.indb 90 1/16/12 2:07 PM