Page 314 - Drilling Technology in Nontechnical Language

P. 314

Chapter 13 – DRILLING PROBLEMS AND SOLUTIONS 305

ground nut shells. Usually some mud would be placed in a separate tank

(probably about 100 bbl), and a mix of LCM types mixed in. The drill bit

will be pulled up the well until it is somewhere close above the top of the

permeable formation, and the LCM mud is pumped to the zone and left

for a while. It is hoped that the LCM will create a nice plaster of material

at the exposed face of the formation. Sometimes it works, and sometimes

it does not.

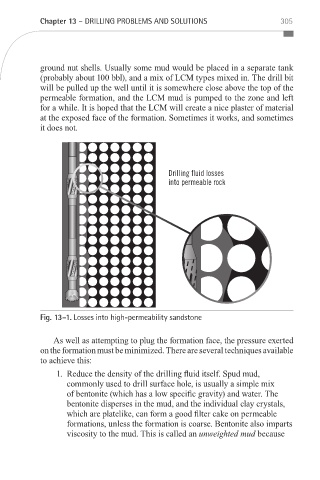

Fig. 13–1. Losses into high-permeability sandstone

As well as attempting to plug the formation face, the pressure exerted

on the formation must be minimized. There are several techniques available

to achieve this:

1. Reduce the density of the drilling fluid itself. Spud mud,

commonly used to drill surface hole, is usually a simple mix

of bentonite (which has a low specific gravity) and water. The

bentonite disperses in the mud, and the individual clay crystals,

which are platelike, can form a good filter cake on permeable

formations, unless the formation is coarse. Bentonite also imparts

viscosity to the mud. This is called an unweighted mud because

_Devereux_Book.indb 305 1/16/12 2:12 PM