Page 193 - Dust Explosions in the Process Industries

P. 193

166 Dust Explosions in the Process Industries

e-

t

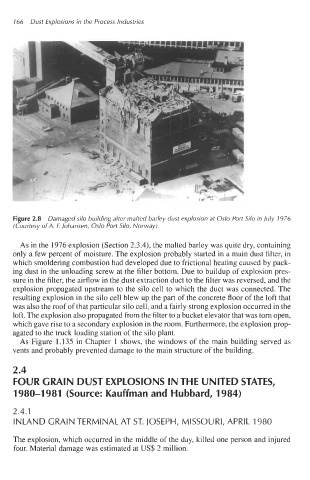

Figure 2.8 Damaged silo building after malted barley dust explosion at Oslo Port Silo in July 1976

(Courtesy ofA. F. Johansen, Oslo Port Silo, Norway).

As in the 1976 explosion (Section 2.3.4), the malted barley was quite dry, containing

only a few percent of moisture. The explosion probably started in a main dust filter, in

which smoldering combustion had developed due to frictional heating caused by pack-

ing dust in the unloading screw at the filter bottom. Due to buildup of explosion pres-

sure in the filter, the airflow in the dust extraction duct to the filter was reversed, and the

explosion propagated upstream to the silo cell to which the duct was connected. The

resulting explosion in the silo cell blew up the part of the concrete floor of the loft that

was also the roof of that particular silo cell, and a fairly strong explosion occurred in the

loft. The explosion also propagated from the filter to a bucket elevator that was tom open,

which gave rise to a secondary explosion in the room. Furthermore, the explosion prop-

agated to the truck loading station of the silo plant.

As Figure 1.135 in Chapter 1 shows, the windows of the main building served as

vents and probably prevented damage to the main structure of the building.

2.4

FOUR GRAIN DUST EXPLOSIONS IN THE UNITED STATES,

1980-1 981 (Source: Kauffman and Hubbard, 1984)

2.4.1

INLAND GRAIN TERMINAL AT ST. JOSEPH, MISSOURI, APRIL 1980

The explosion, which occurred in the middle of the day, killed one person and injured

four. Material damage was estimated at US$ 2 million.