Page 284 - Dust Explosions in the Process Industries

P. 284

Propagation of Flames in Dust Clouds 253

tongue on a limited section of the surface was noted at a particle temperature of 2070 &-

50 K. With further heating to 2170 K, the flame tongue propagated to the entire particle

surface, and the particle temperatureremained constant at 2170 K during the subsequent

burning. This temperature is slightly lower than the melting point of the oxide, and

Ermakov et al. challenged the oxide melting point hypothesis. They concluded that the

ignition temperature obtained in their experiments showed that ignition is not caused by

melting the oxide film but the destruction of the integrity of the film due to thermome-

chanical stresses arising during the heating process. This was indicated by photographs

of the particle surface at the time that the flame tongue appeared. No influenceof the inci-

dent heating flux density on the stationary combustion temperature of the particle was

detected. See Section 9.2.3.2 in Chapter 9 for further works on aluminum particles.

4.1.2

MAGNESIUM

Cassel and Liebman (1959) found that ignition temperatures of magnesium particles in

air did not differ from those in pure oxygen. Therefore, they excluded oxygen diffusion

as the reaction rate controlling mechanism in the ignition process and proposed a theory

based on a simple chemical controlArrhenius term for describing the rate of heat gener-

ation per unit of particle surface area. An average value of the activation energy of 160k

13 J/mole was derived from the available experimental data.

Cassel and Liebman (1963) measured the ignition temperatures of single magnesium

particles of 20-120 pm diameter by dropping the particles into a furnace containinghot

air of known temperature. They found that the minimum air temperature for ignition

decreased systematicallywith increasing particle size, being 1015 K for a 20 pm diam-

eter particle, 950 K for 50 pm, and 910 K for 120 pm.

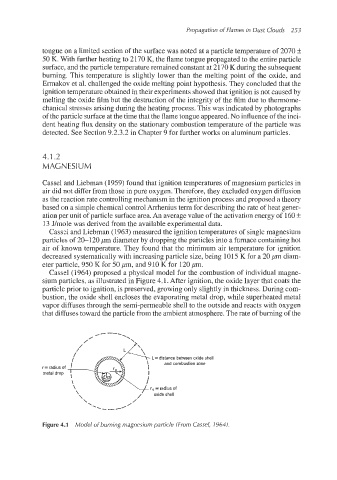

Cassel (1964) proposed a physical model for the combustion of individual magne-

sium particles, as illustrated in Figure 4.1. After ignition, the oxide layer that coats the

particle prior to ignition, is preserved, growing only slightly in thickness. During com-

bustion, the oxide shell encloses the evaporating metal drop, while superheated metal

vapor diffuses through the semi-permeable shell to the outside and reacts with oxygen

that diffuses toward the particle from the ambientatmosphere. The rate of burning of the

.

/----.

'.

/'

/

//

I .L=distance between oxide shell

I and combustion zone

r = radius of

metal drop 7

I

\

\ ro = radius of

'\ /- oxide shell

Figure 4.1 Model of burning magnesium particle (From Cassel, 1964).