Page 30 - Dust Explosions in the Process Industries

P. 30

Dust Explosions: An Overview 3

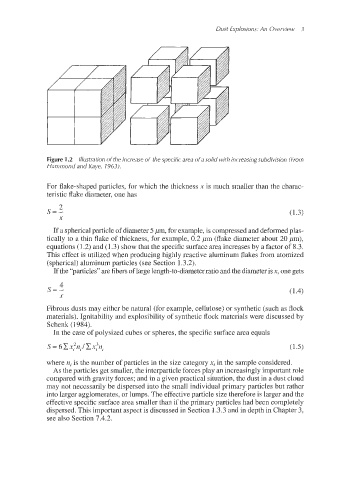

Figure 1.2 lllustralion of the increase of the specific area ofa solid with increasing subdivision (From

Hammond and Kaye, 1963).

For flake-shaped particles, for which the thickness x is much smaller than the charac-

teristic flake diameter, one has

2

S=-

X

If a spherical particle of diameter 5 pm, for example, is compressed and deformed plas-

tically to a thin flake of thickness, for example, 0.2 pm (flake diameter about 20 pm),

equations (1.2) and (1.3) show that the specific surface area increases by a factor of 8.3.

This effect is utilized when producing highly reactive aluminum flakes from atomized

(spherical) aluminum particles (see Section 1.3.2).

If the “particles”are fibers of large length-to-diameterratio and the diameter is x,one gets

S=- 4

X

Fibrous dusts may either be natural (for example, cellulose) or synthetic (such as flock

materials). Ignitability and explosibility of synthetic flock materials were discussed by

Schenk (1984).

In the case of polysized cubes or spheres, the specific surface area equals

S = 6 CxfniI Cx:ni (1.5)

where niis the number of particles in the size category xiin the sample considered.

As the particles get smaller, the interparticleforcesplay an increasinglyimportantrole

compared with gravity forces; and in a given practical situation,the dust in a dust cloud

may not necessarily be dispersed into the small individual primary particles but rather

into larger agglomerates,or lumps. The effective particle size therefore is larger and the

effective specific surface area smaller than if the primary particles had been completely

dispersed. This important aspect is discussed in Section 1.3.3 and in depth in Chapter 3,

see also Section 7.4.2.