Page 522 - Dust Explosions in the Process Industries

P. 522

Assessment of lgnitability 489

and performance of this kind of ignitor. Closed 1m3or 20 liter explosionbombs are often

employed as test vessels (see Sections7.15 and 7.16), and significantpressurerise is taken

as an indicationof explosion. However, some European countrieshave also adopted the

modified Hartmann tube originally proposed by Lutolf (1971) for the yeslno test. In this

apparatus, the ignition source is a comparatively weak electric spark. The argument put

forward in defense of this approach is that none of the dusts classified as nonexplosible

in the modified Hartmann tube test ever caused explosions in the chemical industry.

Bartknecht (1978), on the other hand, warned against the use of the modified Hartmann

tube test for yeslno screening,unless the spark ignition source is replaced by a glowing

resistance wire coil with a temperature of at least 1000°C.

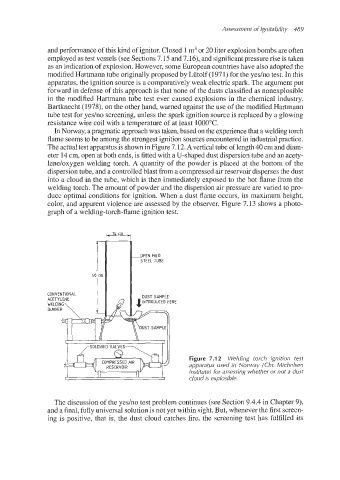

In Norway, a pragmatic approachwas taken, based on the experiencethat a welding torch

flame seems to be among the strongestignition sources encountered in industrialpractice.

The actual test apparatusis shownin Figure 7.12. A vertical tube of length 40 em and diam-

eter 14cm, open at both ends, is fittedwith a U-shaped dust dispersion tube and an acety-

leneloxygen welding torch. A quantity of the powder is placed at the bottom of the

dispersion tube, and a controlled blast from a compressed air reservoir disperses the dust

into a cloud in the tube, which is then immediately exposed to the hot flame from the

welding torch. The amount of powder and the dispersion air pressure are varied to pro-

duce optimal conditions for ignition. When a dust flame occurs, its maximum height,

color, and apparent violence are assessed by the observer. Figure 7.13 shows a photo-

graph of a welding-torch-flame ignition test.

Figure 7.12 Welding torch ignition test

apparatus used in Norway (Chr. Michelsen

Institute) for assessing whether or not a dust

cloud is explosible.

The discussion of the yeslno test problem continues (see Section 9.4.4 in Chapter 9),

and a final, fully universal solution is not yet within sight. But, whenever the first screen-

ing is positive, that is, the dust cloud catches fire, the screening test has fulfilled its