Page 273 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 273

GENERATOR COMPONENTS, AUXILIARIES, AND EXCITATION

13.6 CHAPTER THIRTEEN

SEAL FACE

LANDING STOP KEY VANE BACK PLATE KEY

INBOARD

END

GAS

RESTRICTOR

BALANCE

WEIGHT

OUTBOARD

END

ROTOR SHAFT

VENTILATION

SLOT

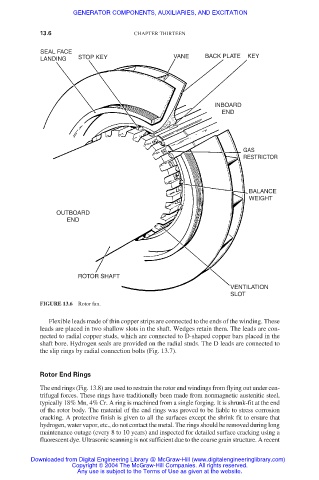

FIGURE 13.6 Rotor fan.

Flexible leads made of thin copper strips are connected to the ends of the winding. These

leads are placed in two shallow slots in the shaft. Wedges retain them. The leads are con-

nected to radial copper studs, which are connected to D-shaped copper bars placed in the

shaft bore. Hydrogen seals are provided on the radial studs. The D leads are connected to

the slip rings by radial connection bolts (Fig. 13.7).

Rotor End Rings

The end rings (Fig. 13.8) are used to restrain the rotor end windings from flying out under cen-

trifugal forces. These rings have traditionally been made from nonmagnetic austenitic steel,

typically 18% Mn, 4% Cr. A ring is machined from a single forging. It is shrunk-fit at the end

of the rotor body. The material of the end rings was proved to be liable to stress corrosion

cracking. A protective finish is given to all the surfaces except the shrink fit to ensure that

hydrogen, water vapor, etc., do not contact the metal. The rings should be removed during long

maintenance outage (every 8 to 10 years) and inspected for detailed surface cracking using a

fluorescent dye. Ultrasonic scanning is not sufficient due to the coarse grain structure. A recent

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.