Page 238 - Electrical Installation in Hazardous Area

P. 238

202 Electrical installations in hazardous areas

A

B

-

Detail of rear inner

corner of compression

element

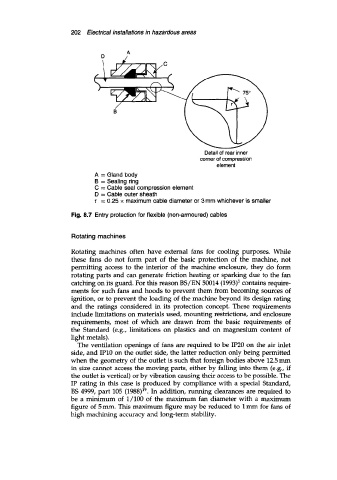

A = Gland body

B = Sealing ring

C = Cable seal compression element

D = Cable outer sheath

r = 0.25 x maximum cable diameter or 3mm whichever is smaller

Fig. 8.7 Entry protection for flexible (non-armoured) cables

Rotating machines

Rotating machines often have external fans for cooling purposes. While

these fans do not form part of the basic protection of the machine, not

permitting access to the interior of the machine enclosure, they do form

rotating parts and can generate friction heating or sparking due to the fan

catching on its guard. For this reason BS/EN 50014 (1993)' contains require-

ments for such fans and hoods to prevent them from becoming sources of

ignition, or to prevent the loading of the machine beyond its design rating

and the ratings considered in its protection concept. These requirements

include limitations on materials used, mounting restrictions, and enclosure

requirements, most of which are drawn from the basic requirements of

the Standard (e.g., limitations on plastics and on magnesium content of

light metals).

The ventilation openings of fans are required to be IP20 on the air inlet

side, and IPlO on the outlet side, the latter reduction only being permitted

when the geometry of the outlet is such that foreign bodies above 12.5mm

in size cannot access the moving parts, either by falling into them (e.g., if

the outlet is vertical) or by vibration causing their access to be possible. The

IP rating in this case is produced by compliance with a special Standard,

BS 4999, part 105 (1988)19. In addition, running clearances are required to

be a minimum of 1/100 of the maximum fan diameter with a maximum

figure of 5mm. This maximum figure may be reduced to 1 mm for fans of

high machining accuracy and long-term stability.