Page 26 - Electrical Installation in Hazardous Area

P. 26

Introduction 5

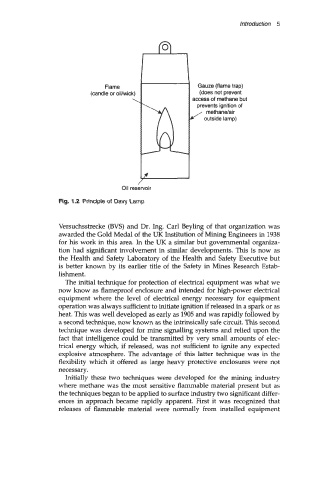

Flame Gauze (flame trap)

(candle or oil/wick) (does not prevent

\ access of methane but

prevents ignition of

methane/ai r

k/ outside lamp)

oil reservoir

Fig. 1.2 Principle of Davy Lamp

Versuchsstrecke (BVS) and Dr. Ing. Carl Beyling of that organization was

awarded the Gold Medal of the UK Institution of Mining Engineers in 1938

for his work in this area. In the UK a similar but governmental organiza-

tion had significant involvement in similar developments. This is now as

the Health and Safety Laboratory of the Health and Safety Executive but

is better known by its earlier title of the Safety in Mines Research Estab-

lishment.

The initial technique for protection of electrical equipment was what we

now know as flameproof enclosure and intended for high-power electrical

equipment where the level of electrical energy necessary for equipment

operation was always sufficient to initiate ignition if released in a spark or as

heat. This was well developed as early as 1905 and was rapidly followed by

a second technique, now known as the intrinsically safe circuit. This second

technique was developed for mine signalling systems and relied upon the

fact that intelligence could be transmitted by very small amounts of elec-

trical energy which, if released, was not sufficient to ignite any expected

explosive atmosphere. The advantage of this latter technique was in the

flexibility which it offered as large heavy protective enclosures were not

necessary.

Initially these two techniques were developed for the mining industry

where methane was the most sensitive flammable material present but as

the techniques began to be applied to surface industry two significant differ-

ences in approach became rapidly apparent. First it was recognized that

releases of flammable material were normally from installed equipment