Page 147 - Embedded Microprocessor Systems Real World Design

P. 147

the normal running current. If the software simultaneously starts multiple motors,

the resulting current surge may disrupt the system electronics or even the proces-

sor itself. It may be necessary for the software to sequence motor startup and

braking to prevent these problems. Software also may need to filter sensors that

are susceptible to radiated interference. In general, it is better to provide such

protection in hardware, but sometimes the nature of the sensor makes it impossi-

ble to filter the interference. This might happen if the sensor must sense very low-

level signals or has to sense over a long cable. In cases like these, the software may

need to perform some filtering.

Other similar cases include turning off PWM-controlled devices while making

sensitive ADC measurements. This includes motors, solenoids, heaters, and so on.

Even DC devices may need to be turned off. A typical example would be a heater

that draws enough current to produce a significant DC drop in the wiring, and

where the heater ground is shared with a temperature sensor such as a thermo-

couple or thermistor. In a case like this, it may be necessary to turn the heater off

so an accurate temperature reading can be made.

Interrupt Protection

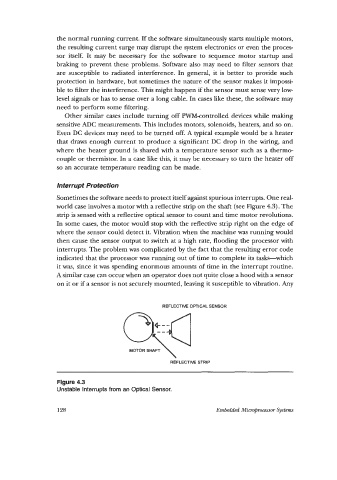

Sometimes the software needs to protect itself against spurious interrupts. One real-

world case involves a motor with a reflective strip on the shaft (see Figure 4.3). The

strip is sensed with a reflective optical sensor to count and time motor revolutions.

In some cases, the motor would stop with the reflective strip right on the edge of

where the sensor could detect it. Vibration when the machine was running would

then cause the sensor output to switch at a high rate, flooding the processor with

interrupts. The problem was complicated by the fact that the resulting error code

indicated that the processor was running out of time to complete its tasks-which

it was, since it was spending enormous amounts of time in the interrupt routine.

A similar case can occur when an operator does not quite close a hood with a sensor

on it or if a sensor is not securely mounted, leaving it susceptible to vibration. Any

REFLECTIVE OPTICAL SENSOR

O\Q

MOTOR

SHAFT

REFLECTIVE STRIP

Figure 4.3

Unstable Interrupts from an Optical Sensor.

128 Embedded Microp-ocessor Systems