Page 44 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 44

P1: FJD Revised Pages

Encyclopedia of Physical Science and Technology EN001-13 May 7, 2001 12:29

266 Adsorption (Chemical Engineering)

For nitrogen production, a carbon molecular sieve ad-

sorbent is generally used. The equilibrium isotherms for

oxygen and nitrogen on carbon molecular sieves are al-

most identical, but the micropore diffusivity of oxygen

∼ 30). A kinetic separation is

is much higher (D O 2 /D N 2

therefore possible, yielding nitrogen as the raffinate prod-

uct. The process could be carried out in a Skarstrom cycle,

but the cycle shown in Fig. 11(b) provides a more attractive

alternative. This system is self-purging because the purge

gas is provided by the residential nitrogen which desorbs

during the “desorption” step. Although high-purity nitro-

gen can be obtained in this way, it is generally more eco-

nomic to produce a nitrogen product of ∼99% purity and

remove the remaining oxygen by hydrogen addition and

catalytic oxidation.

In the zeolite-based PSA process the argon is separated

with the oxygen. For medical applications the presence of

a small amount of argon is of little consequence, but it is

a significant disadvantage for welding since the presence

of even a small amount of argon leads to a significant

reduction of flame temperature and cutting speed. In the

carbon sieve process the argon and nitrogen are separated

together as the raffinate product.

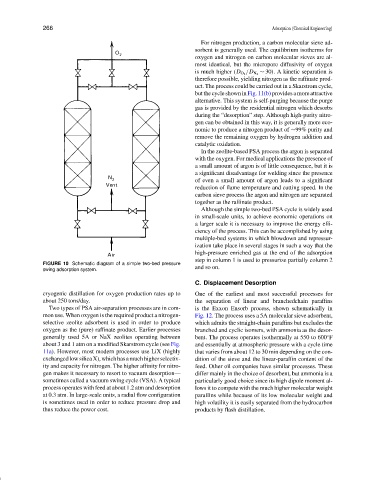

Although the simple two-bed PSA cycle is widely used

in small-scale units, to achieve economic operations on

a larger scale it is necessary to improve the energy effi-

ciency of the process. This can be accomplished by using

multiple-bed systems in which blowdown and repressur-

ization take place in several stages in such a way that the

high-pressure enriched gas at the end of the adsorption

step in column 1 is used to pressurize partially column 2

FIGURE 10 Schematic diagram of a simple two-bed pressure

and so on.

swing adsorption system.

C. Displacement Desorption

cryogenic distillation for oxygen production rates up to One of the earliest and most successful processes for

about 250 tons/day. the separation of linear and branchedchain paraffins

Two types of PSA air-separation processes are in com- is the Exxon Ensorb process, shown schematically in

mon use. When oxygen is the required product a nitrogen- Fig. 12. The process uses a 5A molecular sieve adsorbent,

selective zeolite adsorbent is used in order to produce which admits the straight-chain paraffins but excludes the

oxygen as the (pure) raffinate product. Earlier processes branched and cyclic isomers, with ammonia as the desor-

generally used 5A or NaX zeolites operating between bent. The process operates isothermally at 550 to 600 F

◦

about 3 and 1 atm on a modified Skarstrom cycle (see Fig. and essentially at atmospheric pressure with a cycle time

11a). However, most modern processes use LiX (highly that varies from about 12 to 30 min depending on the con-

exchangedlowsilicaX),whichhasamuchhigherselectiv- dition of the sieve and the linear-paraffin content of the

ity and capacity for nitrogen. The higher affinity for nitro- feed. Other oil companies have similar processes. These

gen makes it necessary to resort to vacuum desorption— differ mainly in the choice of desorbent, but ammonia is a

sometimes called a vacuum swing cycle (VSA). A typical particularly good choice since its high dipole moment al-

process operates with feed at about 1.2 atm and desorption lows it to compete with the much higher molecular weight

at 0.3 atm. In large-scale units, a radial flow configuration paraffins while because of its low molecular weight and

is sometimes used in order to reduce pressure drop and high volatility it is easily separated from the hydrocarbon

thus reduce the power cost. products by flash distillation.