Page 30 - Academic Press Encyclopedia of Physical Science and Technology 3rd Organic Chemistry

P. 30

P1: GLQ Revised Pages

Encyclopedia of Physical Science and Technology EN001F-4 May 7, 2001 16:19

82 Acetylene

such as m-nitrobromobenzene with 3-methyl-1-butyn- as a precursor to form m-aminophenylacetylene, which

3-ol (MB), using a catalyst composed of palladious is an important acetylenic capping agent for polyimide

chloride and triphenylphosphine. The catalyst complex polymers. This is an alternative method of preparing the

[PdCl 2 –P–(C 6 H 5 ) 3 ] is further activated with a catalytic m-amino derivative in place of catalytic hydrogenation,

amount of cuprous iodide, used as promoter. The reaction cited above.

◦

is carried out in an amine solvent at 50–100 C. The re-

sulting nitrophenylhydroxyacetylene is then cleaved with

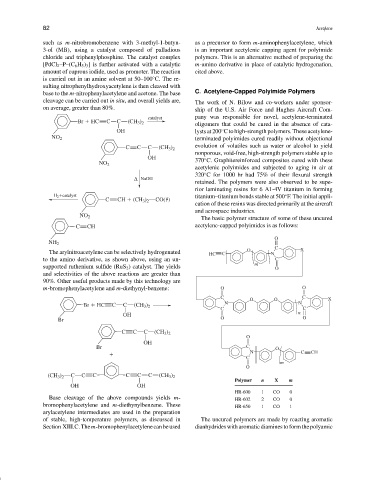

base to the m-nitrophenylacetylene and acetone. The base C. Acetylene-Capped Polyimide Polymers

cleavage can be carried out in situ, and overall yields are, The work of N. Bilow and co-workers under sponsor-

on average, greater than 80%. ship of the U.S. Air Force and Hughes Aircraft Com-

catalyst pany was responsible for novel, acetylene-terminated

Br HC C C (CH 3 ) 2

oligomers that could be cured in the absence of cata-

OH lysts at 200 C to high-strength polymers. These acetylene-

◦

terminated polyimides cured readily without objectional

NO 2

C C C (CH 3 ) 2 evolution of volatiles such as water or alcohol to yield

nonporous, void-free, high-strength polymers stable up to

OH

◦

370 C. Graphitereinforced composites cured with these

NO 2

acetylenic polyimides and subjected to aging in air at

320 C for 1000 hr had 75% of their flexural strength

◦

∆ NaOH

retained. The polymers were also observed to be supe-

rior laminating resins for 6 A1-4V titanium in forming

◦

Η 2 catalyst titanium–titanium bonds stable at 500 F. The initial appli-

C CH (CH 3 ) 2 CO( )

cation of these resins was directed primarily at the aircraft

and aerospace industries.

NO 2

The basic polymer structure of some of these uncured

C CH acetylene-capped polyimides is as follows:

O

NH 2

C X

The arylnitroacetylene can be selectively hydrogenated HC C O N

to the amino derivative, as shown above, using an un- C

m

supported ruthenium sulfide (RuS 2 ) catalyst. The yields O

and selectivities of the above reactions are greater than

90%. Other useful products made by this technology are

m-bromophenylacetylene and m-diethynyl-benzene: O O

C O O C X

Br HC C C (CH 3 ) 2 N N

C C

OH n

Br O O

C C C (CH 3 ) 2

O

OH

Br C O

N C CH

C

m

O

(CH 3 ) 2 C C C C C C (CH 3 ) 2

Polymer n X m

OH OH

HR-600 1 CO 0

Base cleavage of the above compounds yields m- HR-602 2 CO 0

bromophenylacetylene and m-diethynylbenzene. These HR-650 1 CO 1

arylacetylene intermediates are used in the preparation

of stable, high-temperature polymers, as discussed in The uncured polymers are made by reacting aromatic

Section XIII.C.Them-bromophenylacetylenecanbeused dianhydrides with aromatic diamines to form the polyamic