Page 72 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 72

Toxic Waste From Leather Industries 59

drying processes, while emissions of sulfides may be the result of liming or

unhairing and subsequent processes. Hydrogen sulfide is released in tannery

wastewater from alkaline sulfides if the pH is <8.0. Particulate emissions

contain chromium, which may occur [29,30] due to reduction of chromate

or through handling of basic chromic sulfate powder or from the buffing

process [29–31]. Thus, substantial amount of volatile organic compounds

(VOC) are emitted during different tanning processes which may pose

threat to the atmosphere if not controlled properly.

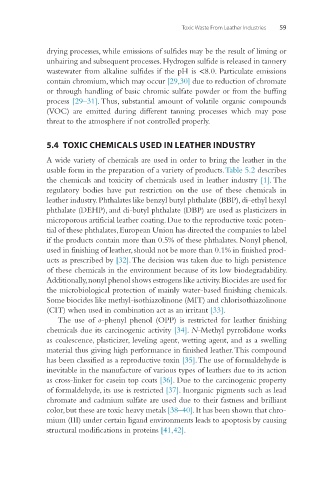

5.4 TOXIC CHEMICALS USED IN LEATHER INDUSTRY

A wide variety of chemicals are used in order to bring the leather in the

usable form in the preparation of a variety of products. Table 5.2 describes

the chemicals and toxicity of chemicals used in leather industry [1]. The

regulatory bodies have put restriction on the use of these chemicals in

leather industry. Phthalates like benzyl butyl phthalate (BBP), di-ethyl hexyl

phthalate (DEHP), and di-butyl phthalate (DBP) are used as plasticizers in

microporous artificial leather coating. Due to the reproductive toxic poten-

tial of these phthalates, European Union has directed the companies to label

if the products contain more than 0.5% of these phthalates. Nonyl phenol,

used in finishing of leather, should not be more than 0.1% in finished prod-

ucts as prescribed by [32]. The decision was taken due to high persistence

of these chemicals in the environment because of its low biodegradability.

Additionally, nonyl phenol shows estrogens like activity. Biocides are used for

the microbiological protection of mainly water-based finishing chemicals.

Some biocides like methyl-isothiazolinone (MIT) and chlorisothiazolinone

(CIT) when used in combination act as an irritant [33].

The use of o-phenyl phenol (OPP) is restricted for leather finishing

chemicals due its carcinogenic activity [34]. N-Methyl pyrrolidone works

as coalescence, plasticizer, leveling agent, wetting agent, and as a swelling

material thus giving high performance in finished leather. This compound

has been classified as a reproductive toxin [35]. The use of formaldehyde is

inevitable in the manufacture of various types of leathers due to its action

as cross-linker for casein top coats [36]. Due to the carcinogenic property

of formaldehyde, its use is restricted [37]. Inorganic pigments such as lead

chromate and cadmium sulfate are used due to their fastness and brilliant

color, but these are toxic heavy metals [38–40]. It has been shown that chro-

mium (III) under certain ligand environments leads to apoptosis by causing

structural modifications in proteins [41,42].