Page 332 - Engineered Interfaces in Fiber Reinforced Composites

P. 332

Chapter 7. Improvement of transverse fracture toughness with interfuw control 313

t L direction

T direction

- Splitting in

longitudinal

lamina

Transverse 1

crack in

transverse (goe)

lamina

0

H'

---J

b 2d b

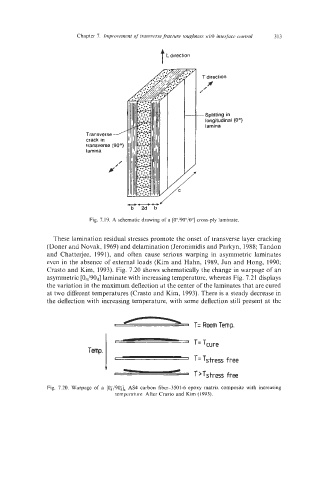

Fig. 7.19. A schematic drawing of a [Oo/9O0/O0] cross-ply laminate

-

These lamination residual stresses promote the onset of transverse layer cracking

(Doner and Novak, 1969) and delamination (Jeronimidis and Parkyn, 1988; Tandon

and Chatterjee, 1991), and often cause serious warping in asymmetric laminates

even in the absence of external loads (Kim and Hahn, 1989, Jun and Hong, 1990;

Crasto and Kim, 1993). Fig. 7.20 shows schematically the change in warpage of an

asymmetric [04/904] laminate with increasing temperature, whereas Fig. 7.2 1 displays

the variation in the maximum deflection at the center of the laminates that are cured

at two different temperatures (Crasto and Kim, 1993). There is a steady decrease in

-

the deflection with increasing temperature, with some deflection still present at the

T=RoomTemp.

Temp. T=Tcure

7 -, T= Tstress free

Fig. 7.20. Warpage of a [0;/90& AS4 carbon fiber-3501-6 epoxy matrix composite with increasing

temperature. After Crasto and Kim (1993).