Page 131 - Engineering Plastics Handbook

P. 131

Acrylonitrile-Butadiene-Styrene (ABS) Resin 105

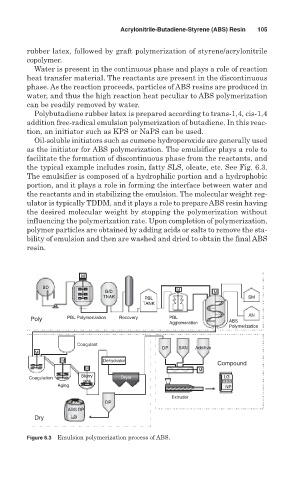

rubber latex, followed by graft polymerization of styrene/acrylonitrile

copolymer.

Water is present in the continuous phase and plays a role of reaction

heat transfer material. The reactants are present in the discontinuous

phase. As the reaction proceeds, particles of ABS resins are produced in

water, and thus the high reaction heat peculiar to ABS polymerization

can be readily removed by water.

Polybutadiene rubber latex is prepared according to trans-1,4, cis-1,4

addition free-radical emulsion polymerization of butadiene. In this reac-

tion, an initiator such as KPS or NaPS can be used.

Oil-soluble initiators such as cumene hydroperoxide are generally used

as the initiator for ABS polymerization. The emulsifier plays a role to

facilitate the formation of discontinuous phase from the reactants, and

the typical example includes rosin, fatty SLS, oleate, etc. See Fig. 6.3.

The emulsifier is composed of a hydrophilic portion and a hydrophobic

portion, and it plays a role in forming the interface between water and

the reactants and in stabilizing the emulsion. The molecular weight reg-

ulator is typically TDDM, and it plays a role to prepare ABS resin having

the desired molecular weight by stopping the polymerization without

influencing the polymerization rate. Upon completion of polymerization,

polymer particles are obtained by adding acids or salts to remove the sta-

bility of emulsion and then are washed and dried to obtain the final ABS

resin.

M M M

BD

B/D M M

TNAK SM

PBL

TANK

AN

Poly PBL Polymerization Recovery PBL

Agglomeration ABS

Polymerization

Coagulant

DP SAN Additive

M

M Dehydrator

Compound

M M

Slurry

Coagulation Dryer LG

tank ABS

Aging NP

Extruder

DP

ABS DP

Dry LG

Figure 6.3 Emulsion polymerization process of ABS.