Page 352 -

P. 352

310 Chapter 11 • Supply Chain Management

Financial Flows

Supplier Manufacturer Distributor Retailer Customer

Information Flows

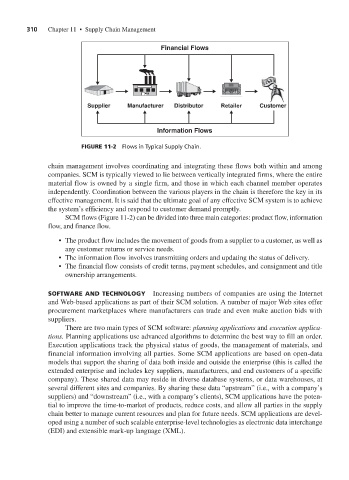

FIGURE 11-2 Flows in Typical Supply Chain.

chain management involves coordinating and integrating these flows both within and among

companies. SCM is typically viewed to lie between vertically integrated firms, where the entire

material flow is owned by a single firm, and those in which each channel member operates

independently. Coordination between the various players in the chain is therefore the key in its

effective management. It is said that the ultimate goal of any effective SCM system is to achieve

the system’s efficiency and respond to customer demand promptly.

SCM flows (Figure 11-2) can be divided into three main categories: product flow, information

flow, and finance flow.

•The product flow includes the movement of goods from a supplier to a customer, as well as

any customer returns or service needs.

•The information flow involves transmitting orders and updating the status of delivery.

•The financial flow consists of credit terms, payment schedules, and consignment and title

ownership arrangements.

SOFTWARE AND TECHNOLOGY Increasing numbers of companies are using the Internet

and Web-based applications as part of their SCM solution. A number of major Web sites offer

procurement marketplaces where manufacturers can trade and even make auction bids with

suppliers.

There are two main types of SCM software: planning applications and execution applica-

tions. Planning applications use advanced algorithms to determine the best way to fill an order.

Execution applications track the physical status of goods, the management of materials, and

financial information involving all parties. Some SCM applications are based on open-data

models that support the sharing of data both inside and outside the enterprise (this is called the

extended enterprise and includes key suppliers, manufacturers, and end customers of a specific

company). These shared data may reside in diverse database systems, or data warehouses, at

several different sites and companies. By sharing these data “upstream” (i.e., with a company’s

suppliers) and “downstream” (i.e., with a company’s clients), SCM applications have the poten-

tial to improve the time-to-market of products, reduce costs, and allow all parties in the supply

chain better to manage current resources and plan for future needs. SCM applications are devel-

oped using a number of such scalable enterprise-level technologies as electronic data interchange

(EDI) and extensible mark-up language (XML).