Page 175 - Estimators Piping Man Hour Manual

P. 175

158 Section Three-ALLOY AND NON-FERROUS FABRICATION

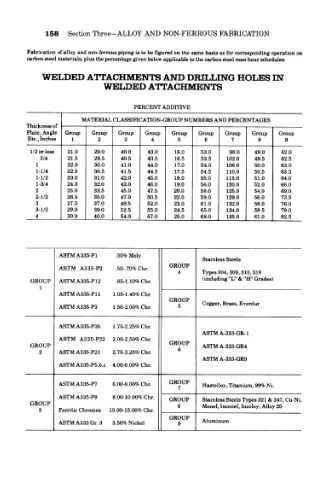

Fabrication of alloy and non-ferrous piping is to be figured on the same basis as for corresponding operation on

carbon steel materials, plus the percentage given below applicable to the carbon steel man hour schedules.

WELDED ATTACHMENTS AND DBILLING HOLES IN

WELDED ATTACHMENTS

MATERIAL CLASSIFICATION-GROUP NUMBERS AND PERCENTAGES

i nicKness 01

mi ' I f

Plate, Angle Group Group Group Group Group Group Group Group Group

Etc., Inches 1 2 3 4 5 6 7 8 9

1/2 or less 21.0 29.0 40.0 43.0 16.0 53.0 98.0 49.0 62.0

3/4 21.5 29.5 40.5 43.5 16.5 53.5 102.0 49.5 62.5

1 22.0 30.0 41.0 44.0 17.0 54.0 106.0 50.0 63.0

1-1/4 22.5 30.5 41.5 44.5 17.5 54.5 110.0 50.5 63.5

1-1/2 23.0 31.0 42.0 45.0 18.0 55.0 115.0 51.0 64.0

1-3/4 24.0 32.0 43.0 46.0 19.0 56.0 120.0 52.0 66.0

2 25.0 33.5 45.0 47.5 20.0 58.0 125.0 54.0 69.0

2-1/2 26.5 35.0 47.0 50.5 22.0 59.0 129.0 56.0 73.5

3 27.5 37.0 49.5 52.0 23.0 61.0 132.0 58.0 76.0

3-1/2 29.0 39.0 52.5 55.0 24.5 65.0 134.0 59.5 79.0

4 30.0 40.0 54.0 57.0 25.0 68.0 135.0 61.0 82.5

ASTM A335-P1 .50% Moly

Stainless Steels

GROUP

ASTM A335-P2 .50-.70% Chr.

4 Types 304, 309, 310, 316

(including "L" & "H" Grades)

GROUP ASTM A335-P12 .85-1.10%Chr.

1

ASTMA335-P11 1.05- 1.45% Chr.

GROUP Copper, Brass, Everdur

ASTM A335-P3 1.50-2.00% Chr. 5

ASTM A335-P3b 1.75-2.25% Chr.

ASTMA-333-GR-1

ASTM A335-P22 2.00-2.50% Chr.

GROUP

GROUP ASTM A-333-GR4

2 ASTMA335-P21 2.75-3.25% Chr. 6

ASTM A-333-GR9

ASTM A335-P5,b,c 4.00-6.00% Chr.

ASTM A335-P7 6.00-8.00% Chr. GROUP Hastelloy, Titanium, 99% Ni.

7

ASTM A335-P9 8.00- 10.00% Chr. GROUP Stainless Steels Types 321 & 347, Cu-Ni,

GROUP 8 Monel, Inconel, Incoloy, Alloy 20

3 Ferritic Chromes 10.00-15.00% Chr.

GROUP

ASTM A333 Gr. 3 3.50% Nickel 9 Aluminum