Page 143 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 143

SOLID-LIQUID SEPARATION AND INTERCEPTORS

SOLID-LIQUID SEPARATION AND INTERCEPTORS 3.11

10000 38,000

9000 34,000

8000 30,000

7000 DN 250 26,500

6000 23,000

5000 19,000

4000 15,000

3500 DN 200

3000 11,400

2500

2000 7600

DN 150

1000 3800

900 3400

800 3000

700 DN 125 2650

600 2300

1900

500 DN 100 1500

FLOW IN GPM 300 1140 FLOW IN l/m

400

950

200

DN 65

570

150 DN 80 760

100 380

90 340

80 300

70 DN 50 265

60 230

50 190

40 150

30 115

20 75

15

1.7 1.4 2.1 2.8 3.5 4.2 4.9 5.6 6.3 7.0 10 14 21 17 28 35 42 49 56 63 KPA

10

.1 .2 .3 .4 .5 .6 .7 .8 .9 1.0 2 3 4 5 6 7 8 9 10 PSI

PRESSURE DROP

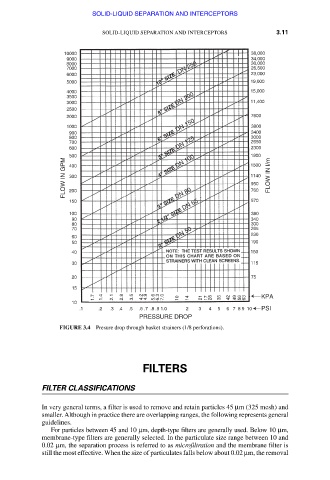

FIGURE 3.4 Presure drop through basket strainers (1/8 perforations).

FILTERS

FILTER CLASSIFICATIONS

In very general terms, a filter is used to remove and retain particles 45 μm (325 mesh) and

smaller. Although in practice there are overlapping ranges, the following represents general

guidelines.

For particles between 45 and 10 μm, depth-type filters are generally used. Below 10 μm,

membrane-type filters are generally selected. In the particulate size range between 10 and

0.02 μm, the separation process is referred to as microfiltration and the membrane filter is

still the most effective. When the size of particulates falls below about 0.02 μm, the removal

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.