Page 32 - Fluid mechanics, heat transfer, and mass transfer

P. 32

VISCOSITY MEASUREMENT 9

➢ In this device, a concentric rotating cylinder

(spindle) spins at a constant rotational speed inside

another cylinder. In general, there is a very small

gap between the walls. This annulus is filled with

the fluid. The torque needed to maintain this

constant rotation rate of the inner spindle is mea-

sured by means of a torsion wire from which the

spindle is suspended. This device is sometimes

called Couette viscometer, named after its discov-

erer. Some types of viscometers rotate the outer

cylinder.

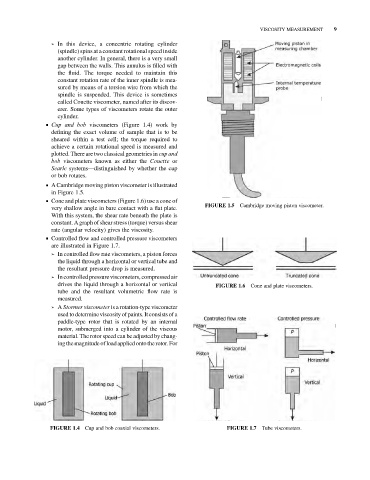

& Cup and bob viscometers (Figure 1.4) work by

defining the exact volume of sample that is to be

sheared within a test cell; the torque required to

achieve a certain rotational speed is measured and

plotted. There are two classical geometries in cup and

bob viscometers known as either the Couette or

Searle systems—distinguished by whether the cup

or bob rotates.

& A Cambridge moving piston viscometer is illustrated

in Figure 1.5.

& Cone and plate viscometers (Figure 1.6) use a cone of

Cambridge moving piston viscometer.

very shallow angle in bare contact with a flat plate. FIGURE 1.5

With this system, the shear rate beneath the plate is

constant. A graph of shear stress (torque) versus shear

rate (angular velocity) gives the viscosity.

& Controlled flow and controlled pressure viscometers

are illustrated in Figure 1.7.

➢ In controlled flow rate viscometers, a piston forces

the liquid through a horizontal or vertical tube and

the resultant pressure drop is measured.

➢ In controlled pressureviscometers, compressed air

drives the liquid through a horizontal or vertical Cone and plate viscometers.

FIGURE 1.6

tube and the resultant volumetric flow rate is

measured.

➢ A Stormer viscometer is a rotation-type viscometer

used to determineviscosity of paints. It consists of a

paddle-type rotor that is rotated by an internal

motor, submerged into a cylinder of the viscous

material. The rotor speed can be adjusted by chang-

ing themagnitude ofloadappliedonto therotor.For

Cup and bob coaxial viscometers. Tube viscometers.

FIGURE 1.4 FIGURE 1.7