Page 54 - Fluid mechanics, heat transfer, and mass transfer

P. 54

WATER HAMMER 31

branch, or tracer line or pumped condensate lines or & A pressure wave as a result of a pump stopping is

heat exchanger tubing. Steam will collapse, since more damaging than a pump starting due to the large

condensate temperature is mostly subcooled in the change in pressure that will continue much longer

lines. after the pump is stopped, compared to start of the

➢ This collapse will release energy in a short period pump.

of time. & Entrained air or temperature changes of the water can

➢ Vacuum is created due to suddenvolume reduction be controlled by pressure relief valves, which are set

by about 1600 times. to open with excess pressure in the line and then

➢ Water rushes into this space from all directions. closed when pressure drops. Relief valves are com-

monly used in pump stations to control pressure

& Flow Shock: Caused by lack of proper drainage

surges and to protect the pump station. Positively

ahead of a steam line isolation valve or steam control

controlled relief valves act as surge suppressors.

valve.

These valves can be an effective method of control-

➢ Changes in power demand from turbines.

ling transients.

➢ Operation of reciprocating pumps.

& However, they must be properly sized and selected.

➢ Changing elevation of a reservoir/storage tank.

& Where pressure drops due to condensation or un-

➢ Waves on a reservoir.

loading operations, giving rise to vacuum in the sys-

➢ Unstable fan or pump characteristics. tem, properly selected and sized vacuum breaker–air

➢ Tube failure in a heat exchanger. release valves can be the least expensive means of

. What are the important phenomenon parameters useful protecting a piping system.

in the analysis of water hammer? & Pump start-up problems can usually be avoided by

increasing the flow slowly to collapse or flush out the

& Velocity of the pressure wave.

voids gently. Also, a simple means of reducing

& Critical time of the phenomenon.

hydraulic surge pressure is to keep pipelinevelocities

& Maximum head developed in the maximum pressure

low. This not only results in lower surge pressures,

time.

but also results in lower drive horsepower and, thus,

& Minimum head developed in the critical time. maximum operating economy.

. What are the precautions to prevent or reduce water & Providing surge tanks in long pipelines to relieve

hammer? pressures generated, storing excess liquid. These

& Designing the system with low velocities. tanks can serve as dampeners for both positive and

& Water hammer often damages centrifugal pumps negative pressures. However, surge tanks for surge

when electric power fails. In this situation, the best control are expensive compared to other devices.

form of prevention is to have automatically con- & Since severity of water hammer is highly dependent

trolled valves, which close slowly. (These valves on the acoustic velocity, a reduction in acoustic

work without electricity or batteries. The direction velocity will reduce hammer. This can be accom-

of the flow controls them.) Closing the valve slowly plished by adding a small quantity of air to a liquid

can moderate the rise in the pressure when the down- system or switching to noncircular piping.

surge wave, resulting from the valve closing, returns & Installing air chambers in systems with frequent

from the reservoir. water hammer problems: shaped like thin, upside-

& Providing slow closing bypasses around fast closing down bottles with a small orifice connection to the

valves. pipe, they are air-filled. The air compresses to absorb

& Ensuring correct flow directions in the process plant the shock, protecting the fixture and piping.

can reduce or even prevent pressure wave problems.

& With air-operated seat valves, incorrect direction of

flow can cause the valve plug to close rapidly against

the valve seat inducing pressure waves.

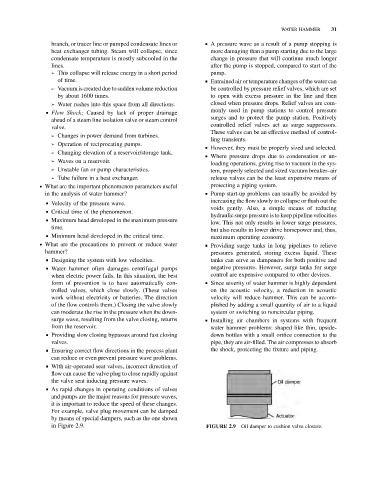

& As rapid changes in operating conditions of valves

and pumps are the major reasons for pressure waves,

it is important to reduce the speed of these changes.

For example, valve plug movement can be damped

by means of special dampers, such as the one shown

in Figure 2.9. FIGURE 2.9 Oil damper to cushion valve closure.