Page 213 - Forensic Structural Engineering Handbook

P. 213

THE ENGINEERING INVESTIGATION PROCESS 6.15

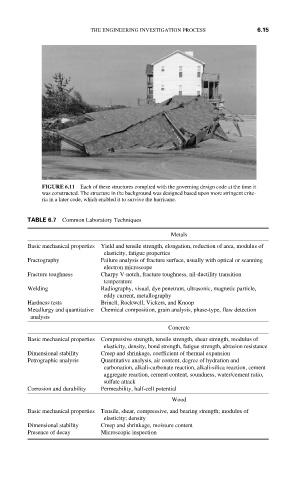

FIGURE 6.11 Each of these structures complied with the governing design code at the time it

was constructed. The structure in the background was designed based upon more stringent crite-

ria in a later code, which enabled it to survive the hurricane.

TABLE 6.7 Common Laboratory Techniques

Metals

Basic mechanical properties Yield and tensile strength, elongation, reduction of area, modulus of

elasticity, fatigue properties

Fractography Failure analysis of fracture surface, usually with optical or scanning

electron microscope

Fracture toughness Charpy V-notch, fracture toughness, nil-ductility transition

temperature

Welding Radiography, visual, dye penetrant, ultrasonic, magnetic particle,

eddy current, metallography

Hardness tests Brinell, Rockwell, Vickers, and Knoop

Metallurgy and quantitative Chemical composition, grain analysis, phase-type, flaw detection

analysis

Concrete

Basic mechanical properties Compressive strength, tensile strength, shear strength, modulus of

elasticity, density, bond strength, fatigue strength, abrasion resistance

Dimensional stability Creep and shrinkage, coefficient of thermal expansion

Petrographic analysis Quantitative analysis, air content, degree of hydration and

carbonation, alkali-carbonate reaction, alkali-silica reaction, cement

aggregate reaction, cement content, soundness, water/cement ratio,

sulfate attack

Corrosion and durability Permeability, half-cell potential

Wood

Basic mechanical properties Tensile, shear, compressive, and bearing strength; modulus of

elasticity; density

Dimensional stability Creep and shrinkage, moisture content

Presence of decay Microscopic inspection