Page 417 - Forensic Structural Engineering Handbook

P. 417

12.8 MATERIAL-SPECIFIC FORENSIC ANALYSES

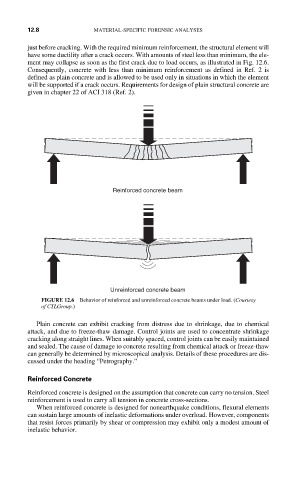

just before cracking. With the required minimum reinforcement, the structural element will

have some ductility after a crack occurs. With amounts of steel less than minimum, the ele-

ment may collapse as soon as the first crack due to load occurs, as illustrated in Fig. 12.6.

Consequently, concrete with less than minimum reinforcement as defined in Ref. 2 is

defined as plain concrete and is allowed to be used only in situations in which the element

will be supported if a crack occurs. Requirements for design of plain structural concrete are

given in chapter 22 of ACI 318 (Ref. 2).

Reinforced concrete beam

Unreinforced concrete beam

FIGURE 12.6 Behavior of reinforced and unreinforced concrete beams under load. (Courtesy

of CTLGroup.)

Plain concrete can exhibit cracking from distress due to shrinkage, due to chemical

attack, and due to freeze-thaw damage. Control joints are used to concentrate shrinkage

cracking along straight lines. When suitably spaced, control joints can be easily maintained

and sealed. The cause of damage to concrete resulting from chemical attack or freeze-thaw

can generally be determined by microscopical analysis. Details of these procedures are dis-

cussed under the heading “Petrography.”

Reinforced Concrete

Reinforced concrete is designed on the assumption that concrete can carry no tension. Steel

reinforcement is used to carry all tension in concrete cross-sections.

When reinforced concrete is designed for nonearthquake conditions, flexural elements

can sustain large amounts of inelastic deformations under overload. However, components

that resist forces primarily by shear or compression may exhibit only a modest amount of

inelastic behavior.