Page 519 - Forensic Structural Engineering Handbook

P. 519

14.10 MATERIAL-SPECIFIC FORENSIC ANALYSES

analyzed using the above formula, and stresses were within published allowables. An

extensive research program in the 1960s provided both a reduction in allowable cross-grain

tension stresses for western softwoods and a revised design approach for tapered curved

members. The iterative design procedure resulting from that approach is presented in the

9

AITC Timber Construction Manual. Reinforcing perpendicular to grain, where required

per the design approach for nonprismatic members, solved the problem of beam separations

and has been in common use since the late 1960s. (See Case Study 3, Tinora High School.)

All timber connections rely on the dubious cross-grain tension capacity of timber, some

more than others. It is obvious that connections loaded perpendicular to the grain create

cross-grain tension. Extending the connection closer to the unloaded edge of the timber

helps this situation as the design criteria in NDS Section 3.4.3.3 indicates. Round or circu-

lar connections parallel to the grain create component forces perpendicular to the grain, and

most parallel-grain connections are near the end of a member where it is easier to open the

grain of the timber. (See Case Study 4, University of Puget Sound Field House.)

This is not a valid reason to return to square nails used a century ago, but the forensic

engineer should be aware of these cross-grain tension forces. Just installing the connectors

can create cross-grain tension forces, which is why the appropriate installation pattern for

3

timber rivets is described in Section 13.1.2.1 of the NDS with exterior rivets driven first.

Connector Stiffness Compatibility. A C factor in Section 10.3.6 of the NDS reduces the

g

effectiveness of multiple bolt and split ring connections due to uneven load distribution

relating to the axial stiffness of the two connecting pieces. There is no mention of the accu-

racy of drilled holes for bolts which may have an even greater effect. Prying action across

the grain (creating cross-grain tension) is a common cause of connection failure in timber

as very high cross-grain tension forces can be generated. Hidden end connections on beams

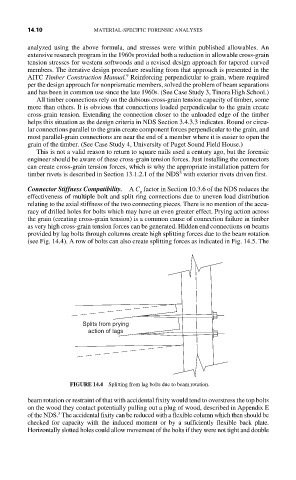

provided by lag bolts through columns create high splitting forces due to the beam rotation

(see Fig. 14.4). A row of bolts can also create splitting forces as indicated in Fig. 14.5. The

Splits from prying

action of lags

FIGURE 14.4 Splitting from lag bolts due to beam rotation.

beam rotation or restraint of that with accidental fixity would tend to overstress the top bolts

on the wood they contact potentially pulling out a plug of wood, described in Appendix E

3

of the NDS. The accidental fixity can be reduced with a flexible column which then should be

checked for capacity with the induced moment or by a sufficiently flexible back plate.

Horizontally slotted holes could allow movement of the bolts if they were not tight and double