Page 253 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 253

1656_C005.fm Page 233 Monday, May 23, 2005 5:47 PM

Fracture Mechanisms in Metals 233

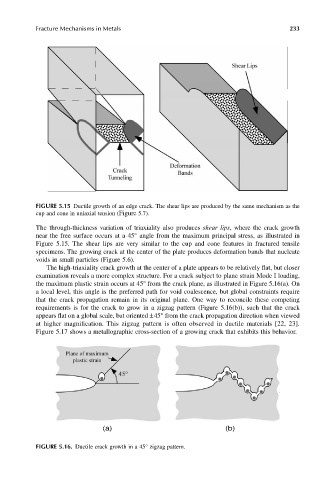

FIGURE 5.15 Ductile growth of an edge crack. The shear lips are produced by the same mechanism as the

cup and cone in uniaxial tension (Figure 5.7).

The through-thickness variation of triaxiality also produces shear lips, where the crack growth

near the free surface occurs at a 45° angle from the maximum principal stress, as illustrated in

Figure 5.15. The shear lips are very similar to the cup and cone features in fractured tensile

specimens. The growing crack at the center of the plate produces deformation bands that nucleate

voids in small particles (Figure 5.6).

The high-triaxiality crack growth at the center of a plate appears to be relatively flat, but closer

examination reveals a more complex structure. For a crack subject to plane strain Mode I loading,

the maximum plastic strain occurs at 45° from the crack plane, as illustrated in Figure 5.16(a). On

a local level, this angle is the preferred path for void coalescence, but global constraints require

that the crack propagation remain in its original plane. One way to reconcile these competing

requirements is for the crack to grow in a zigzag pattern (Figure 5.16(b)), such that the crack

appears flat on a global scale, but oriented ±45° from the crack propagation direction when viewed

at higher magnification. This zigzag pattern is often observed in ductile materials [22, 23].

Figure 5.17 shows a metallographic cross-section of a growing crack that exhibits this behavior.

(a) (b)

FIGURE 5.16. Ductile crack growth in a 45° zigzag pattern.