Page 120 - Fundamentals of Air Pollution 3E

P. 120

90 6. Sources of Air Pollution

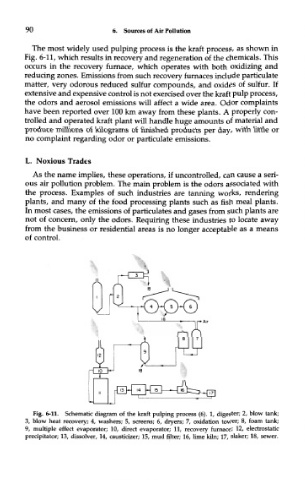

The most widely used pulping process is the kraft process, as shown in

Fig. 6-11, which results in recovery and regeneration of the chemicals. This

occurs in the recovery furnace, which operates with both oxidizing and

reducing zones. Emissions from such recovery furnaces include particulate

matter, very odorous reduced sulfur compounds, and oxides of sulfur. If

extensive and expensive control is not exercised over the kraft pulp process,

the odors and aerosol emissions will affect a wide area. Odor complaints

have been reported over 100 km away from these plants. A properly con-

trolled and operated kraft plant will handle huge amounts of material and

produce millions of kilograms of finished products per day, with little or

no complaint regarding odor or particulate emissions.

L. Noxious Trades

As the name implies, these operations, if uncontrolled, can cause a seri-

ous air pollution problem. The main problem is the odors associated with

the process. Examples of such industries are tanning works, rendering

plants, and many of the food processing plants such as fish meal plants.

In most cases, the emissions of particulates and gases from such plants are

not of concern, only the odors. Requiring these industries to locate away

from the business or residential areas is no longer acceptable as a means

of control.

Fig. 6-11. Schematic diagram of the kraft pulping process (6). 1, digester; 2, blow tank;

3, blow heat recovery; 4, washers; 5, screens; 6, dryers; 7, oxidation tower; 8, foam tank;

9, multiple effect evaporator; 10, direct evaporator; 11, recovery furnace; 12, electrostatic

precipitator; 13, dissolver, 14, causticizer; 15, mud filter; 16, lime kiln; 17, slaker; 18, sewer.