Page 652 - Handbook of Thermal Analysis of Construction Materials

P. 652

620 Chapter 15 - Roofing Materials

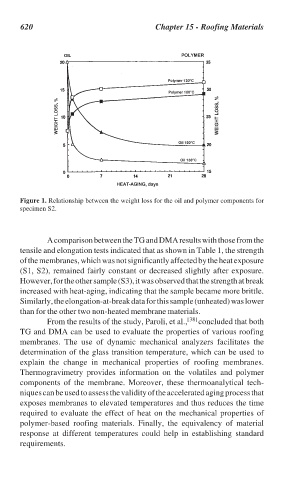

Figure 1. Relationship between the weight loss for the oil and polymer components for

specimen S2.

A comparison between the TG and DMA results with those from the

tensile and elongation tests indicated that as shown in Table 1, the strength

of the membranes, which was not significantly affected by the heat exposure

(S1, S2), remained fairly constant or decreased slightly after exposure.

However, for the other sample (S3), it was observed that the strength at break

increased with heat-aging, indicating that the sample became more brittle.

Similarly, the elongation-at-break data for this sample (unheated) was lower

than for the other two non-heated membrane materials.

From the results of the study, Paroli, et al., [38] concluded that both

TG and DMA can be used to evaluate the properties of various roofing

membranes. The use of dynamic mechanical analyzers facilitates the

determination of the glass transition temperature, which can be used to

explain the change in mechanical properties of roofing membranes.

Thermogravimetry provides information on the volatiles and polymer

components of the membrane. Moreover, these thermoanalytical tech-

niques can be used to assess the validity of the accelerated aging process that

exposes membranes to elevated temperatures and thus reduces the time

required to evaluate the effect of heat on the mechanical properties of

polymer-based roofing materials. Finally, the equivalency of material

response at different temperatures could help in establishing standard

requirements.