Page 194 - Handbook Of Multiphase Flow Assurance

P. 194

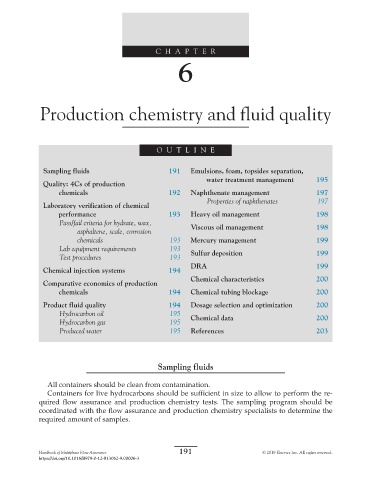

CHAPTER

6

Production chemistry and fluid quality

OUTLINE

Sampling fluids 191 Emulsions, foam, topsides separation,

water treatment management 195

Quality: 4Cs of production

chemicals 192 Naphthenate management 197

Properties of naphthenates 197

Laboratory verification of chemical

performance 193 Heavy oil management 198

Pass/fail criteria for hydrate, wax, Viscous oil management 198

asphaltene, scale, corrosion

chemicals 193 Mercury management 199

Lab equipment requirements 193 Sulfur deposition 199

Test procedures 193

DRA 199

Chemical injection systems 194

Chemical characteristics 200

Comparative economics of production

chemicals 194 Chemical tubing blockage 200

Product fluid quality 194 Dosage selection and optimization 200

Hydrocarbon oil 195 Chemical data 200

Hydrocarbon gas 195

Produced water 195 References 203

Sampling fluids

All containers should be clean from contamination.

Containers for live hydrocarbons should be sufficient in size to allow to perform the re-

quired flow assurance and production chemistry tests. The sampling program should be

coordinated with the flow assurance and production chemistry specialists to determine the

required amount of samples.

Handbook of Multiphase Flow Assurance 191 © 2019 Elsevier Inc. All rights reserved.

https://doi.org/10.1016/B978-0-12-813062-9.00006-3