Page 20 - Handbook Of Multiphase Flow Assurance

P. 20

14 1. Introduction

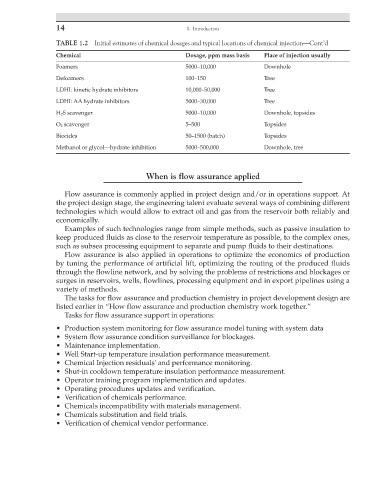

TABLE 1.2 Initial estimates of chemical dosages and typical locations of chemical injection —Cont’d

Chemical Dosage, ppm mass basis Place of injection usually

Foamers 5000–10,000 Downhole

Defoamers 100–150 Tree

LDHI: kinetic hydrate inhibitors 10,000–50,000 Tree

LDHI: AA hydrate inhibitors 5000–30,000 Tree

H 2 S scavenger 5000–10,000 Downhole, topsides

O 2 scavenger 5–500 Topsides

Biocides 50–1500 (batch) Topsides

Methanol or glycol—hydrate inhibition 5000–500,000 Downhole, tree

When is flow assurance applied

Flow assurance is commonly applied in project design and/or in operations support. At

the project design stage, the engineering talent evaluate several ways of combining different

technologies which would allow to extract oil and gas from the reservoir both reliably and

economically.

Examples of such technologies range from simple methods, such as passive insulation to

keep produced fluids as close to the reservoir temperature as possible, to the complex ones,

such as subsea processing equipment to separate and pump fluids to their destinations.

Flow assurance is also applied in operations to optimize the economics of production

by tuning the performance of artificial lift, optimizing the routing of the produced fluids

through the flowline network, and by solving the problems of restrictions and blockages or

surges in reservoirs, wells, flowlines, processing equipment and in export pipelines using a

variety of methods.

The tasks for flow assurance and production chemistry in project development design are

listed earlier in “How flow assurance and production chemistry work together.”

Tasks for flow assurance support in operations:

• Production system monitoring for flow assurance model tuning with system data

• System flow assurance condition surveillance for blockages.

• Maintenance implementation.

• Well Start-up temperature insulation performance measurement.

• Chemical Injection residuals' and performance monitoring.

• Shut-in cooldown temperature insulation performance measurement.

• Operator training program implementation and updates.

• Operating procedures updates and verification.

• Verification of chemicals performance.

• Chemicals incompatibility with materials management.

• Chemicals substitution and field trials.

• Verification of chemical vendor performance.