Page 185 - Handbook of Thermal Analysis of Construction Materials

P. 185

168 Chapter 4 - Introduction to Concrete Admixtures

One of the important applications of water reducers is their ability

to increase the workability characteristics or slump at a constant w/c ratio,

without affecting strengths. The degree to which slump increases depends

on the admixture dosage level, cement content, and the type of aggregate.

Slump can be increased by 100% by water reducers. The hydroxycarboxylic

acid-based water reducers seem to promote higher slumps values than those

based on lignosulfonates. Slump loss occurs rapidly in the presence of water

reducers. However, water reducers allow longer periods between mixing

and placing of concrete without detrimental effects.

Extensive work has been carried out on the effect of lignosulfonate

on the hydration of individual compounds as well as on cement itself. The

effects are similar to what has already been described under the previous

section on “Retarders.”

The effect of carboxylic acids such as gluconic acid, and carboxylic

acid and sugars such as glucose or sucrose, on portland cement hydration

is very similar to that of lignosulfonate, although different percentages of

admixtures are required to obtain similar effects.

Generally, water reducers retard both the very early hydration

(initial set) and early hydration (final set) of portland cement whereas they

increase the degree of hydration at later ages. In some cases, an acceleration

of the very early hydration, promoted by carboxylic acids or carbohydrates,

causes quick and early stiffening.

At equal dosages, all water reducers are effective in producing

concrete of equal or higher compressive strength than that of reference

concrete. At equal cement content, air content, and slump, the water

reducers increase the 28 day strength by about 10–20%. Table 9 shows the

influence of lignosulfonate type admixture on the compressive strength of

concrete. [36] Water reduction varies between 5 and 8%.

Although the increase in strength may be explained by water

reduction, higher strengths, in many cases, are greater than what would be

expected from the reduction in w/c ratio.

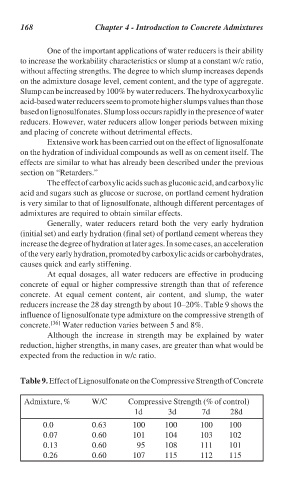

Table 9. Effect of Lignosulfonate on the Compressive Strength of Concrete

Admixture, % W/C Compressive Strength (% of control)

1d 3d 7d 28d

0.0 0.63 100 100 100 100

0.07 0.60 101 104 103 102

0.13 0.60 95 108 111 101

0.26 0.60 107 115 112 115