Page 350 - Handbook of Thermal Analysis of Construction Materials

P. 350

326 Chapter 8 - Supplementary Cementing Materials

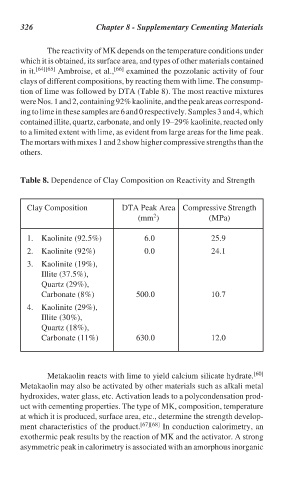

The reactivity of MK depends on the temperature conditions under

which it is obtained, its surface area, and types of other materials contained

in it. [64][65] Ambroise, et al., [66] examined the pozzolanic activity of four

clays of different compositions, by reacting them with lime. The consump-

tion of lime was followed by DTA (Table 8). The most reactive mixtures

were Nos. 1 and 2, containing 92% kaolinite, and the peak areas correspond-

ing to lime in these samples are 6 and 0 respectively. Samples 3 and 4, which

contained illite, quartz, carbonate, and only 19–29% kaolinite, reacted only

to a limited extent with lime, as evident from large areas for the lime peak.

The mortars with mixes 1 and 2 show higher compressive strengths than the

others.

Table 8. Dependence of Clay Composition on Reactivity and Strength

Clay Composition DTA Peak Area Compressive Strength

2

(mm ) (MPa)

1. Kaolinite (92.5%) 6.0 25.9

2. Kaolinite (92%) 0.0 24.1

3. Kaolinite (19%),

Illite (37.5%),

Quartz (29%),

Carbonate (8%) 500.0 10.7

4. Kaolinite (29%),

Illite (30%),

Quartz (18%),

Carbonate (11%) 630.0 12.0

Metakaolin reacts with lime to yield calcium silicate hydrate. [60]

Metakaolin may also be activated by other materials such as alkali metal

hydroxides, water glass, etc. Activation leads to a polycondensation prod-

uct with cementing properties. The type of MK, composition, temperature

at which it is produced, surface area, etc., determine the strength develop-

ment characteristics of the product. [67][68] In conduction calorimetry, an

exothermic peak results by the reaction of MK and the activator. A strong

asymmetric peak in calorimetry is associated with an amorphous inorganic