Page 402 - Handbook of Thermal Analysis of Construction Materials

P. 402

Section 6.0 - Phosphate Cement Systems 379

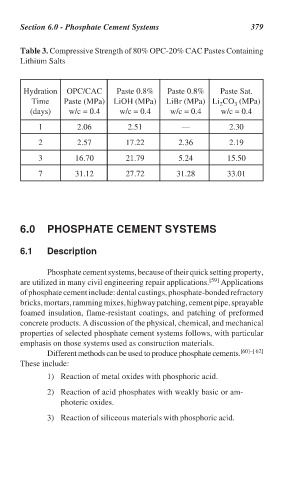

Table 3. Compressive Strength of 80% OPC-20% CAC Pastes Containing

Lithium Salts

Hydration OPC/CAC Paste 0.8% Paste 0.8% Paste Sat.

Time Paste (MPa) LiOH (MPa) LiBr (MPa) Li CO (MPa)

2

3

(days) w/c = 0.4 w/c = 0.4 w/c = 0.4 w/c = 0.4

1 2.06 2.51 — 2.30

2 2.57 17.22 2.36 2.19

3 16.70 21.79 5.24 15.50

7 31.12 27.72 31.28 33.01

6.0 PHOSPHATE CEMENT SYSTEMS

6.1 Description

Phosphate cement systems, because of their quick setting property,

are utilized in many civil engineering repair applications. [59] Applications

of phosphate cement include: dental castings, phosphate-bonded refractory

bricks, mortars, ramming mixes, highway patching, cement pipe, sprayable

foamed insulation, flame-resistant coatings, and patching of preformed

concrete products. A discussion of the physical, chemical, and mechanical

properties of selected phosphate cement systems follows, with particular

emphasis on those systems used as construction materials.

Different methods can be used to produce phosphate cements. [60]–[ 62]

These include:

1) Reaction of metal oxides with phosphoric acid.

2) Reaction of acid phosphates with weakly basic or am-

photeric oxides.

3) Reaction of siliceous materials with phosphoric acid.