Page 548 - Handbook of Thermal Analysis of Construction Materials

P. 548

Section 3.0 - Applications 517

3.8 Solid Waste in Clay Bricks

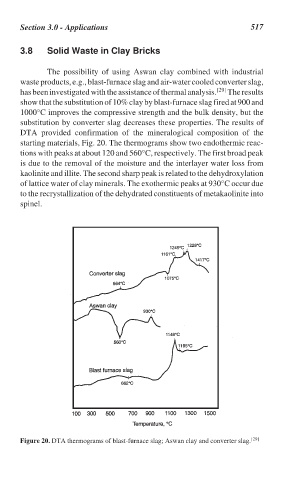

The possibility of using Aswan clay combined with industrial

waste products, e.g., blast-furnace slag and air-water cooled converter slag,

has been investigated with the assistance of thermal analysis. [29] The results

show that the substitution of 10% clay by blast-furnace slag fired at 900 and

1000°C improves the compressive strength and the bulk density, but the

substitution by converter slag decreases these properties. The results of

DTA provided confirmation of the mineralogical composition of the

starting materials, Fig. 20. The thermograms show two endothermic reac-

tions with peaks at about 120 and 560°C, respectively. The first broad peak

is due to the removal of the moisture and the interlayer water loss from

kaolinite and illite. The second sharp peak is related to the dehydroxylation

of lattice water of clay minerals. The exothermic peaks at 930°C occur due

to the recrystallization of the dehydrated constituents of metakaolinite into

spinel.

Figure 20. DTA thermograms of blast-furnace slag; Aswan clay and converter slag. [29]