Page 12 - Handbook of Adhesives and Sealants

P. 12

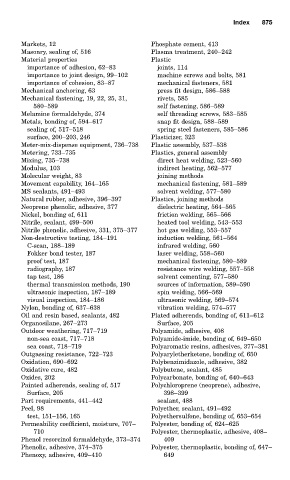

Index 875

Markets, 12 Phosphate cement, 413

Masonry, sealing of, 516 Plasma treatment, 240–242

Material properties Plastic

importance of adhesion, 62–83 joints, 114

importance to joint design, 99–102 machine screws and bolts, 581

importance of cohesion, 83–87 mechanical fasteners, 581

Mechanical anchoring, 63 press fit design, 586–588

Mechanical fastening, 19, 22, 25, 31, rivets, 585

580–589 self fastening, 586–589

Melamine formaldehyde, 374 self threading screws, 583–585

Metals, bonding of, 594–617 snap fit design, 588–589

sealing of, 517–518 spring steel fasteners, 585–586

surface, 200–203, 246 Plasticizer, 323

Meter-mix-dispense equipment, 736–738 Plastic assembly, 537–538

Metering, 733–735 Plastics, general assembly

Mixing, 735–738 direct heat welding, 523–560

Modulus, 103 indirect heating, 562–577

Molecular weight, 83 joining methods

Movement capability, 164–165 mechanical fastening, 581–589

MS sealants, 491–493 solvent welding, 577–580

Natural rubber, adhesive, 396–397 Plastics, joining methods

Neoprene phenolic, adhesive, 377 dielectric heating, 564–565

Nickel, bonding of, 611 friction welding, 565–566

Nitrile, sealant, 499–500 heated tool welding, 543–553

Nitrile phenolic, adhesive, 331, 375–377 hot gas welding, 553–557

Non-destructive testing, 184–191 induction welding, 561–564

C-scan, 188–189 infrared welding, 560

Fokker bond tester, 187 laser welding, 558–560

proof test, 187 mechanical fastening, 580–589

radiography, 187 resistance wire welding, 557–558

tap test, 186 solvent cementing, 577–580

thermal transmission methods, 190 sources of information, 589–590

ultrasonic inspection, 187–189 spin welding, 566–569

visual inspection, 184–186 ultrasonic welding, 569–574

Nylon, bonding of, 637–638 vibration welding, 574–577

Oil and resin based, sealants, 482 Plated adherends, bonding of, 611–612

Organosilane, 267–273 Surface, 205

Outdoor weathering, 717–719 Polyamide, adhesive, 408

non-sea coast, 717–718 Polyamide-imide, bonding of, 649–650

sea coast, 718–719 Polyaromatic resins, adhesives, 377–381

Outgassing resistance, 722–723 Polyaryletherketone, bonding of, 650

Oxidation, 690–692 Polybenzimidazole, adhesive, 382

Oxidative cure, 482 Polybutene, sealant, 485

Oxides, 202 Polycarbonate, bonding of, 640–643

Painted adherends, sealing of, 517 Polychloroprene (neoprene), adhesive,

Surface, 205 398–399

Part requirements, 441–442 sealant, 488

Peel, 98 Polyether, sealant, 491–492

test, 151–156, 165 Polyethersulfone, bonding of, 653–654

Permeability coefficient, moisture, 707– Polyester, bonding of, 624–625

710 Polyester, thermoplastic, adhesive, 408–

Phenol resorcinol formaldehyde, 373–374 409

Phenolic, adhesive, 374–375 Polyester, thermoplastic, bonding of, 647–

Phenoxy, adhesive, 409–410 649