Page 126 - Handbook of Adhesives and Sealants

P. 126

Joint Design 95

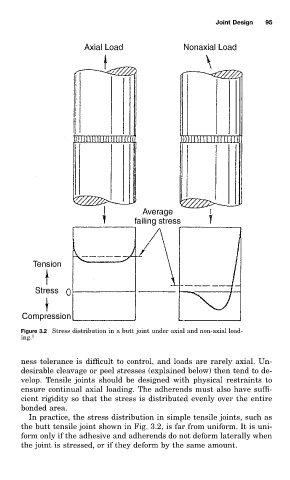

Figure 3.2 Stress distribution in a butt joint under axial and non-axial load-

ing. 1

ness tolerance is difficult to control, and loads are rarely axial. Un-

desirable cleavage or peel stresses (explained below) then tend to de-

velop. Tensile joints should be designed with physical restraints to

ensure continual axial loading. The adherends must also have suffi-

cient rigidity so that the stress is distributed evenly over the entire

bonded area.

In practice, the stress distribution in simple tensile joints, such as

the butt tensile joint shown in Fig. 3.2, is far from uniform. It is uni-

form only if the adhesive and adherends do not deform laterally when

the joint is stressed, or if they deform by the same amount.