Page 134 - Handbook of Adhesives and Sealants

P. 134

Joint Design 103

cept this displacement differential, the flexibility of the adhesive is,

involved.

The stiffness of the adherend is characterized by the product of the

Young’s modulus, E, and the adherend thickness, t. Then Et of each

adherend becomes an important factor in the shear stress distribution.

As the product Et becomes large, the shear stress distribution becomes

more uniform.

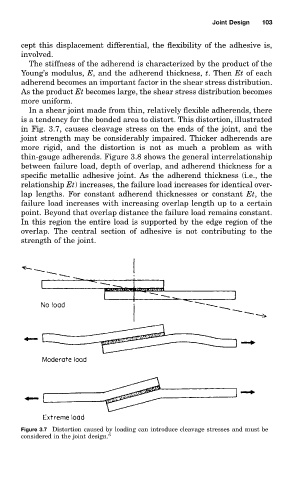

In a shear joint made from thin, relatively flexible adherends, there

is a tendency for the bonded area to distort. This distortion, illustrated

in Fig. 3.7, causes cleavage stress on the ends of the joint, and the

joint strength may be considerably impaired. Thicker adherends are

more rigid, and the distortion is not as much a problem as with

thin-gauge adherends. Figure 3.8 shows the general interrelationship

between failure load, depth of overlap, and adherend thickness for a

specific metallic adhesive joint. As the adherend thickness (i.e., the

relationship Et) increases, the failure load increases for identical over-

lap lengths. For constant adherend thicknesses or constant Et, the

failure load increases with increasing overlap length up to a certain

point. Beyond that overlap distance the failure load remains constant.

In this region the entire load is supported by the edge region of the

overlap. The central section of adhesive is not contributing to the

strength of the joint.

Figure 3.7 Distortion caused by loading can introduce cleavage stresses and must be

considered in the joint design. 6