Page 167 - Handbook of Adhesives and Sealants

P. 167

Standard Test Methods 137

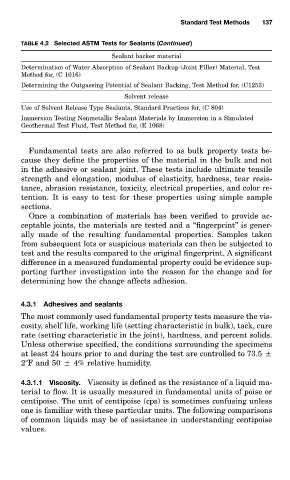

TABLE 4.2 Selected ASTM Tests for Sealants (Continued)

Sealant backer material

Determination of Water Absorption of Sealant Backup (Joint Filler) Material, Test

Method for, (C 1016)

Determining the Outgassing Potential of Sealant Backing, Test Method for, (C1253)

Solvent release

Use of Solvent Release Type Sealants, Standard Practices for, (C 804)

Immersion Testing Nonmetallic Sealant Materials by Immersion in a Simulated

Geothermal Test Fluid, Test Method for, (E 1068)

Fundamental tests are also referred to as bulk property tests be-

cause they define the properties of the material in the bulk and not

in the adhesive or sealant joint. These tests include ultimate tensile

strength and elongation, modulus of elasticity, hardness, tear resis-

tance, abrasion resistance, toxicity, electrical properties, and color re-

tention. It is easy to test for these properties using simple sample

sections.

Once a combination of materials has been verified to provide ac-

ceptable joints, the materials are tested and a ‘‘fingerprint’’ is gener-

ally made of the resulting fundamental properties. Samples taken

from subsequent lots or suspicious materials can then be subjected to

test and the results compared to the original fingerprint. A significant

difference in a measured fundamental property could be evidence sup-

porting further investigation into the reason for the change and for

determining how the change affects adhesion.

4.3.1 Adhesives and sealants

The most commonly used fundamental property tests measure the vis-

cosity, shelf life, working life (setting characteristic in bulk), tack, cure

rate (setting characteristic in the joint), hardness, and percent solids.

Unless otherwise specified, the conditions surrounding the specimens

at least 24 hours prior to and during the test are controlled to 73.5

2 F and 50 4% relative humidity.

4.3.1.1 Viscosity. Viscosity is defined as the resistance of a liquid ma-

terial to flow. It is usually measured in fundamental units of poise or

centipoise. The unit of centipoise (cps) is sometimes confusing unless

one is familiar with these particular units. The following comparisons

of common liquids may be of assistance in understanding centipoise

values.