Page 181 - Handbook of Adhesives and Sealants

P. 181

Standard Test Methods 151

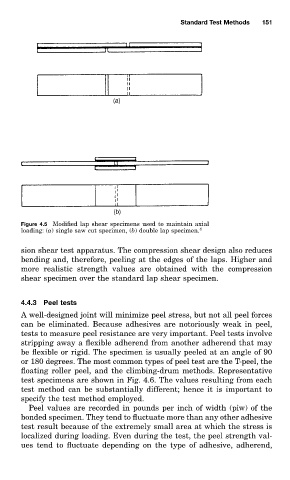

Figure 4.5 Modified lap shear specimens used to maintain axial

loading: (a) single saw cut specimen, (b) double lap specimen. 4

sion shear test apparatus. The compression shear design also reduces

bending and, therefore, peeling at the edges of the laps. Higher and

more realistic strength values are obtained with the compression

shear specimen over the standard lap shear specimen.

4.4.3 Peel tests

A well-designed joint will minimize peel stress, but not all peel forces

can be eliminated. Because adhesives are notoriously weak in peel,

tests to measure peel resistance are very important. Peel tests involve

stripping away a flexible adherend from another adherend that may

be flexible or rigid. The specimen is usually peeled at an angle of 90

or 180 degrees. The most common types of peel test are the T-peel, the

floating roller peel, and the climbing-drum methods. Representative

test specimens are shown in Fig. 4.6. The values resulting from each

test method can be substantially different; hence it is important to

specify the test method employed.

Peel values are recorded in pounds per inch of width (piw) of the

bonded specimen. They tend to fluctuate more than any other adhesive

test result because of the extremely small area at which the stress is

localized during loading. Even during the test, the peel strength val-

ues tend to fluctuate depending on the type of adhesive, adherend,