Page 188 - Handbook of Adhesives and Sealants

P. 188

158 Chapter Four

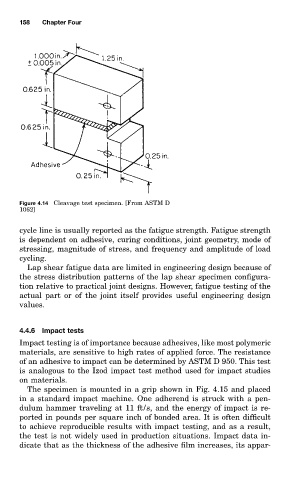

Figure 4.14 Cleavage test specimen. [From ASTM D

1062]

cycle line is usually reported as the fatigue strength. Fatigue strength

is dependent on adhesive, curing conditions, joint geometry, mode of

stressing, magnitude of stress, and frequency and amplitude of load

cycling.

Lap shear fatigue data are limited in engineering design because of

the stress distribution patterns of the lap shear specimen configura-

tion relative to practical joint designs. However, fatigue testing of the

actual part or of the joint itself provides useful engineering design

values.

4.4.6 Impact tests

Impact testing is of importance because adhesives, like most polymeric

materials, are sensitive to high rates of applied force. The resistance

of an adhesive to impact can be determined by ASTM D 950. This test

is analogous to the Izod impact test method used for impact studies

on materials.

The specimen is mounted in a grip shown in Fig. 4.15 and placed

in a standard impact machine. One adherend is struck with a pen-

dulum hammer traveling at 11 ft/s, and the energy of impact is re-

ported in pounds per square inch of bonded area. It is often difficult

to achieve reproducible results with impact testing, and as a result,

the test is not widely used in production situations. Impact data in-

dicate that as the thickness of the adhesive film increases, its appar-