Page 241 - Handbook of Adhesives and Sealants

P. 241

210 Chapter Six

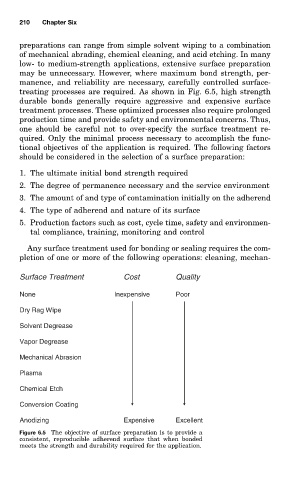

preparations can range from simple solvent wiping to a combination

of mechanical abrading, chemical cleaning, and acid etching. In many

low- to medium-strength applications, extensive surface preparation

may be unnecessary. However, where maximum bond strength, per-

manence, and reliability are necessary, carefully controlled surface-

treating processes are required. As shown in Fig. 6.5, high strength

durable bonds generally require aggressive and expensive surface

treatment processes. These optimized processes also require prolonged

production time and provide safety and environmental concerns. Thus,

one should be careful not to over-specify the surface treatment re-

quired. Only the minimal process necessary to accomplish the func-

tional objectives of the application is required. The following factors

should be considered in the selection of a surface preparation:

1. The ultimate initial bond strength required

2. The degree of permanence necessary and the service environment

3. The amount of and type of contamination initially on the adherend

4. The type of adherend and nature of its surface

5. Production factors such as cost, cycle time, safety and environmen-

tal compliance, training, monitoring and control

Any surface treatment used for bonding or sealing requires the com-

pletion of one or more of the following operations: cleaning, mechan-

Surface Treatment Cost Quality

None Inexpensive Poor

Dry Rag Wipe

Solvent Degrease

Vapor Degrease

Mechanical Abrasion

Plasma

Chemical Etch

Conversion Coating

Anodizing Expensive Excellent

Figure 6.5 The objective of surface preparation is to provide a

consistent, reproducible adherend surface that when bonded

meets the strength and durability required for the application.